The Price Of Asphalt Batch Plant Must Be Fair

When it comes to investing in an asphalt batch plant, finding the right balance between cost and quality is paramount. The price of this essential piece of equipment should not only fit your budget but also align with the plant’s features and performance. In this article, we will delve into the factors that influence the pricing of asphalt batch plants and why fairness in pricing is crucial for making a wise investment.

Factors Influencing Asphalt Batch Plant Prices

Plant Capacity

The capacity of an asphalt batch plant significantly affects its price, and plants are typically categorized into three main capacities:

Small Capacity Plants

Small capacity plants are suitable for localized projects with lower demands. Their affordability caters to those with budget constraints.

Medium Capacity Plants

Medium capacity plants strike a balance between size and output, making them versatile and practical for a wide range of construction projects.

Large Capacity Plants

Large capacity plants are designed for high-volume production and are essential for major infrastructure projects and extensive road networks. Their higher price of large hot mix plants reflects their capability.

Technical Features

The incorporation of advanced technical features can also impact the price of an asphalt batch plant. Here are some key aspects to consider:

Advanced Control Systems

Plants equipped with state-of-the-art control systems offer precise control over mixing and production processes. These advanced features often come at a premium cost.

Environmental Compliance

As environmental regulations become more stringent, asphalt batch plants with eco-friendly technologies and compliance measures may have higher initial asphalt batch plant prices but contribute to sustainability in the long run.

Brand and Reputation

The reputation and brand of the manufacturer can play a significant role in pricing:

Established Manufacturers

Reputable and well-established manufacturers often command higher prices due to their proven track record of producing high-quality, reliable equipment.

New Entrants

New entrants to the market may offer more competitive pricing to establish themselves but might lack the extensive history and credibility of established manufacturers.

The Cost-Quality Balance

Quality and Longevity

While price is a critical factor, it should not compromise the quality of the asphalt batch plant. Investing in a higher-priced, high-quality asphalt mixer plant can result in extended longevity and reduced maintenance costs over time.

Maintenance and Operational Costs

Consider the long-term operational and maintenance costs when evaluating the fairness of the initial price. A slightly higher upfront cost may translate into significant savings in maintenance and repairs in the future.

Ensuring a Fair Price

Research and Comparative Analysis

Before making a purchase, conduct thorough research and comparative analysis of available options. Compare prices, features, and manufacturer reputations to ensure fairness in pricing.

Negotiating with Manufacturers

Don’t hesitate to engage in negotiations with manufacturers. They may be willing to offer discounts or flexible financing options that make the purchase price more equitable. If you choose AIMIX manufacturer, you can browse our machines on this web page: https://aimixasphaltplant.com.

Consideration of Long-Term Benefits

Evaluate the long-term benefits of the asphalt batch plant. A fair price should be viewed in the context of the plant’s performance, durability, and overall value it brings to your projects.

In conclusion, while the price of an asphalt batch plant is a critical factor in the decision-making process, fairness in pricing should be assessed alongside the plant’s features, quality, and long-term benefits. A well-informed and balanced approach to purchasing ensures that you receive the best value for your investment in this vital piece of construction equipment.

High-Quality Rail Mounted Gantry Cranes – Your Lifting Solution

In the dynamic world of material handling and industrial logistics, efficiency, precision, and safety are paramount. Rail mounted gantry cranes, often referred to as RMGs, have emerged as indispensable workhorses in numerous industries, from container terminals and intermodal yards to manufacturing facilities and distribution centers. These remarkable machines, with their ability to seamlessly move heavy loads with precision, have revolutionized the way goods are handled and transported. In this article, we will explore the world of high-quality rail mounted gantry cranes, their key features, diverse applications, and why they may be the perfect lifting solution for your business.

The Essence of Rail Mounted Gantry Cranes

Before diving into the multitude of applications and advantages that rail mounted gantry cranes bring to the table, it’s crucial to understand their fundamental design and components:

- Rail System: RMGs are designed to run on a dedicated rail system, which provides stability and precise movement within the working area. This rail system allows the crane to traverse containers, materials, or products with unparalleled accuracy.

- Gantry Structure: The gantry structure consists of vertical legs and horizontal beams that form a rectangular frame. This structure supports the trolley, hoist, and other essential components.

- Hoisting Mechanism: The hoisting mechanism is responsible for lifting and lowering heavy loads. It often consists of a winch, cable drum, and a lifting hook or attachment.

- Trolley: The trolley is mounted on the gantry structure and can move horizontally along it. This movement allows for precise positioning of the load.

- Control System: Advanced control systems enable operators to manage the crane‘s movements with precision, ensuring safe and efficient material handling.

Applications Across Industries

Rail mounted gantry cranes have found a multitude of applications across various industries:

- Container Terminals: Perhaps the most well-known use of RMGs is in container terminals, where they efficiently load and unload containers from ships, stack them in storage yards, and arrange them for transportation.

- Intermodal Yards: In intermodal facilities, these cranes transfer containers between trains, trucks, and storage areas, facilitating seamless cargo transport between different modes of transportation.

- Manufacturing: Manufacturers utilize RMGs for handling heavy machinery, raw materials, and finished products within their production facilities. This enhances workflow efficiency and reduces manual labor.

- Distribution Centers: Large distribution centers rely on RMGs to organize and transport goods, optimizing storage space and expediting order fulfillment.

- Mining: In mining operations, rail mounted gantry cranes play a critical role in moving ore, equipment, and materials efficiently within the mining site.

- Construction: Construction companies use RMGs to lift and position heavy construction materials, equipment, and prefab components, enhancing construction efficiency.

Why Choose High-Quality RMGs?

- Precision and Efficiency: High-quality rail mounted gantry cranes are engineered for precision. Their automated systems allow for accurate load positioning and reduced handling times, increasing overall operational efficiency.

- Safety: Safety is paramount in industrial settings. High-quality RMGs are equipped with advanced safety features, including collision avoidance systems, load monitoring, and emergency shutdown capabilities.

- Customization: These cranes can be tailored to suit specific operational needs, with options for different lifting capacities, spans, and hoist configurations.

- Durability: A quality RMG is built to withstand heavy usage and harsh environmental conditions, ensuring a long operational life and minimal downtime.

- Reduced Labor Costs: By automating material handling tasks, businesses can reduce labor costs and the risk of accidents associated with manual lifting.

The Role of RMGs in Modern Industry

In the ever-evolving landscape of industry and logistics, rail mounted gantry cranes have become pivotal in streamlining operations and increasing overall productivity. Here’s a closer look at their role:

- Container Handling: In the shipping and logistics sector, RMGs have revolutionized container handling by dramatically reducing loading and unloading times, allowing for the efficient movement of goods globally. The rail mounted container gantry cranes have been widely used for different kinds of containers handling.

- Supply Chain Optimization: RMGs facilitate supply chain optimization by expediting the movement of materials and products, helping businesses meet customer demands and reduce lead times.

- Infrastructure Development: RMGs are essential in the development of critical infrastructure, including ports, rail terminals, and distribution hubs, which are the lifeblood of the global economy.

- Heavy Manufacturing: In heavy manufacturing, RMGs play a crucial role in transporting and positioning large machinery and equipment, ultimately speeding up production processes.

- Safety Culture: The safety features of high-quality RMGs contribute to the fostering of a safety culture within organizations, prioritizing the well-being of workers and reducing the likelihood of accidents.

Investing in Your Future

Choosing high-quality rail mounted gantry cranes is not just a short-term investment; it’s a strategic move that can significantly impact your business’s long-term success. These overhead gantry cranes have the power to revolutionize material handling, drive efficiency, and enhance safety in your operations.

So, if you’re seeking a lifting solution that combines precision, efficiency, and durability, consider exploring the world of high-quality rail mounted gantry cranes. Whether you’re operating a bustling container terminal or managing a manufacturing facility, these cranes can be tailored to meet your unique needs, helping you stay competitive in an ever-changing industrial landscape.

Choosing an Affordable Asphalt Batching Plant: Tips and Considerations

Selecting the right asphalt batching plant can be a challenging task. Before diving into the intricate details of manufacturers, models, and prices, it’s crucial to determine whether you need a stationary asphalt mixing plant or a portable version, especially if you have a batching plant or a mixing truck. Let’s explore the key factors to consider when searching for the ideal asphalt batching plant.

1. Type of Plant

Begin by deciding whether a stationary or portable plant suits your needs best. Each has its advantages, so make an informed choice based on your specific requirements.

If you opt for a stationary plant, research reputable manufacturers known for producing quality equipment in various sizes and capacities. Ensure that the asphalt batching plant you select can consistently produce the required amount of asphalt mix for your projects.

Consider the possibility of purchasing a used stationary plant. Many businesses upgrade or liquidate, offering used asphalt batching plants at discounted prices. Additionally, you can explore listings for used mixing trucks and mobile batching plants.

2. Evaluating Your Needs

Determine the daily and batch-wise asphalt production requirements for your projects. This information is crucial for choosing the right asphalt production plant that aligns with your operational needs. Check whether this kind of asphalt plant can meet your requirements through video:

3. Price Comparison

When browsing through available plants, it’s essential to ensure that you get the best value for your investment. Asphalt batching plants come in a range of price points, and you want to avoid overpaying. In the used equipment market, you may even encounter listings with a ‘best offer’ option, which allows for negotiation.

Whether you’re considering a new or used plant, be prepared to negotiate for the best price. Familiarize yourself with the features and options available for these plants, as this knowledge will enable you to make an informed decision and secure a reasonable asphalt batch plant price.

In conclusion, choosing the right asphalt batching plant is a significant business decision that requires careful consideration. By determining your daily asphalt production needs, understanding the advantages of stationary and portable plants, and negotiating effectively, you can find an asphalt batching plant that meets your requirements at a reasonable price. Making the right choice ensures the success of your projects and contributes to your business’s long-term profitability. You can get reasonable price if you choose AIMIX company, request quotation here: aimixasphaltplant.com.

The Crucial Role of Towing Winches in the Maritime Industry

The maritime industry is a complex web of activities that keep the global economy afloat. From massive cargo vessels to offshore oil rigs, ships of all sizes and types crisscross the world’s oceans, performing vital tasks. In this intricate dance of maritime operations, towing winches emerge as unsung heroes, silently playing a pivotal role in ensuring safety, efficiency, and order on the high seas. This article explores the importance of towing winches in the maritime industry and their crucial role in towing operations.

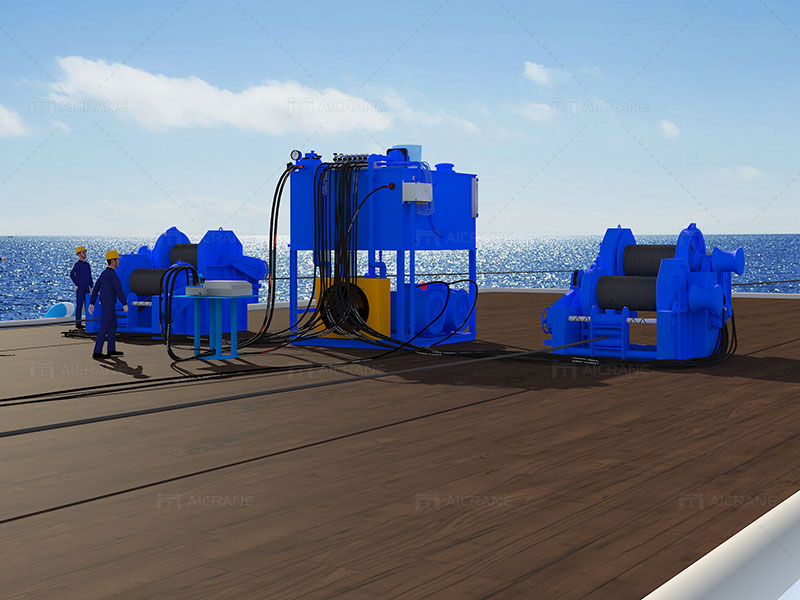

Understanding Towing Winches

Towing winches are robust, specialized machines designed to handle the unique challenges of towing operations in the maritime industry. They come in various configurations and sizes, catering to the specific needs of different vessels and towing tasks. These tow winches are typically powered by hydraulic, electric, or mechanical systems, providing the muscle required for towing heavy loads, be it another vessel in distress, a barge, or even offshore structures.

Key Functions of Towing Winches

Towing Operations: The primary function of towing winches is to facilitate the safe and efficient towing of vessels or structures. Towing winches provide the necessary pulling force to control the movement of the towed object, ensuring it remains under control and follows the desired course. This function is critical in emergency situations, such as towing a disabled vessel to safety or relocating offshore installations.

Mooring Assistance: Towing winches often double as mooring winches when not engaged in towing operations. They assist in securing vessels to docks, jetties, or other mooring points. This ensures that ships remain stable while loading, unloading, or waiting for their next voyage.

Dynamic Positioning: In some offshore applications, such as drilling rigs or research vessels, dynamic positioning is crucial to maintain a specific location without anchoring. Towing winches can be used to adjust the positioning of the vessel, compensating for environmental factors like currents and waves, thus enabling precise and stable offshore operations.

Anchor Handling: In offshore industries, towing winches are often employed for anchor handling operations. These winches are used to deploy, retrieve, and position heavy anchors on oil rigs, floating production units, or other offshore structures. Anchor handling is critical for maintaining the stability and safety of such installations.

Significance of Towing Winches in the Maritime Industry

Safety: Safety is paramount in the maritime industry, and towing winches play a vital role in ensuring it. During emergencies, such as towing a distressed vessel to safety or evacuating personnel from a hazardous location, these winch machines provide the necessary control and force. This helps prevent accidents, injuries, and potential environmental disasters.

Efficiency: Efficiency is a key driver of success in the highly competitive maritime sector. Towing winches enable efficient towing and mooring operations, reducing turnaround times for vessels and minimizing disruptions to port operations. This translates into cost savings and increased profitability for shipping companies and port operators.

Versatility: Towing winches are remarkably versatile and adaptable. They can be customized to meet the specific needs of different vessels and towing scenarios, making them indispensable tools for a wide range of maritime applications.

Environmental Protection: Towing winches contribute to environmental protection by aiding in the safe towing of distressed vessels. Rapid response and controlled towing prevent oil spills and other ecological disasters, mitigating the industry’s impact on the marine environment.

Reliability: In the harsh and unforgiving marine environment, reliability is paramount. Towing winches are built to withstand extreme conditions and rigorous use. Their robust construction ensures they operate reliably when called upon, even in adverse weather or emergency situations.

Cost-Effective Solutions: Towing winches offer cost-effective solutions to the challenges faced by the maritime industry. By providing the necessary force and control for towing and mooring operations, they help streamline processes, reduce downtime, and cut operational costs.

Conclusion

Towing winches are the unsung heroes of the maritime industry, quietly ensuring the safety, efficiency, and order of maritime operations. From towing distressed vessels to facilitating dynamic positioning and anchor handling, these versatile machines are indispensable assets in the complex world of maritime logistics. Their significance extends far beyond their mechanical functions, encompassing safety, efficiency, versatility, environmental protection, and reliability.

As the maritime industry continues to evolve, the role of electric or hydraulic towing winches remains undiminished. They stand as a testament to human ingenuity, engineering prowess, and the enduring commitment to safety and efficiency on the high seas. In the ever-changing landscape of global trade and transportation, towing winches remain steadfast, helping ships navigate the waves and navigate their way to success in the maritime industry.

How To Judge The Reliable Mobile Crushing Plant Manufacturers

Judging reliable mobile crushing plant manufacturers involves careful research and evaluation to ensure you’re selecting a reputable and trustworthy supplier. Here are key factors to consider when assessing mobile crusher plant manufacturers:

Reputation and Experience

Look for manufacturers with a strong reputation in the industry. Established companies with years of experience are more likely to produce quality equipment and provide reliable customer support.

Quality and Technology

Evaluate the quality of their mobile crushing plants. Consider factors such as the materials used in construction, durability of components, and incorporation of advanced technology for efficient and reliable operation.

Certifications and Standards

Check if the manufacturer holds relevant certifications and adheres to international quality standards. Certifications such as ISO 9001 signify a commitment to quality and consistent production processes, click in reliable China mobile crusher plant manufacturer AIMIX for more details.

Customer Reviews and References

Read customer reviews and testimonials from previous buyers. Positive feedback indicates customer satisfaction and a manufacturer’s reliability. You can also request references to directly inquire about their experience.

Product Range and Customization

Evaluate the variety of mobile crushing plants offered by the manufacturer. A wide product range suggests their expertise and capability to meet different customer needs. Inquire if they offer customization options to tailor the equipment to your specific requirements.

After-Sales Support

Reliable manufacturers provide comprehensive after-sales support, including technical assistance, spare parts availability, and maintenance services. Inquire about their support offerings and response times.

Warranty and Service Contracts

Review the warranty terms provided with their mobile crushing plants. A reputable manufacturer should offer a reasonable warranty period and optional service contracts for ongoing support.

Technical Expertise

Assess the manufacturer’s technical knowledge and expertise. Engage in discussions about the design, operation, and maintenance of their equipment to gauge their understanding of the industry.

Transparency and Communication

Consider their communication responsiveness and willingness to provide detailed information about their products. Transparent communication reflects their commitment to customer satisfaction.

Visit Manufacturing Facilities

If feasible, schedule a visit to the manufacturer’s facilities. This allows you to assess their production processes, quality control measures, and overall operations.

Innovation and Research

Look for manufacturers that invest in research and development to innovate and improve their products over time. A commitment to continuous improvement indicates a reliable manufacturer.

Financial Stability

Evaluate the financial stability of the manufacturer. A financially sound company is more likely to deliver on its commitments and provide ongoing support.

Network and Global Presence

Consider manufacturers with a widespread distribution network and global presence. This indicates their reach and ability to serve customers in different regions.

Comparison and Quotes

Obtain quotes and detailed information from multiple manufacturers. Compare not only the prices but also the features, support, and overall value offered by each.

Industry Recognition and Awards

Research if the manufacturer has received any industry recognition, awards, or accolades for their products or services.

By thoroughly evaluating these factors and conducting extensive research, you can make an informed decision when choosing a reliable mobile crushing plant manufacturer that aligns with your needs and priorities.

Here are cases from AIMIX, you can check, an objective evaluation is the only way to truly understand the strengths and weaknesses of a mobile crusher manufacturer.

Revolutionizing Mobile Asphalt Mixing Plants: The Power of Automated Production Lines

In the realm of road construction, the mobile asphalt mixing plant has emerged as a game-changer, offering flexibility and efficiency for projects of varying scales. However, the relentless pursuit of innovation has brought forth a new era – one where automation takes center stage, transforming these plants into powerhouses of productivity. In this article, we delve into the impact of automated production lines on mobile asphalt mixing plants, revolutionizing the industry and paving the way for a more sustainable future.

Streamlining Operations: Simplifying Efficiency with Automated Production Lines

The integration of automated production lines marks a paradigm shift in the efficiency of mobile asphalt mixing plants (мобильный асфальтобетонный завод купить из Китая AIMIXGROUP). These advanced systems streamline the production process, enabling seamless coordination between various components. Automation replaces manual intervention, reducing human errors and increasing precision.

In the fast-paced world of road construction, time is of the essence. Thanks to automation, mobile asphalt mixing plants can now operate with enhanced speed and accuracy, delivering superior asphalt mixtures for every project.

AIMIXGROUP is a trailblazer in this transformative journey, empowering mobile asphalt mixing plant operators with state-of-the-art automation technologies. With years of experience as a leading asphalt equipment manufacturer and distributor, AIMIXGROUP has been at the forefront of revolutionizing the industry.

Efficiency Redefined: Enhancing Productivity through Automation

The impact of automated production lines on mobile asphalt mixing plants is evident in the simplification of operations. Operators can now navigate the entire production process through intuitive control interfaces, minimizing the learning curve and optimizing performance.

With the click of a button, operators can effortlessly oversee material input, heating, mixing, and loading. This newfound ease of operation not only boosts productivity but also fosters a more pleasant working environment.

AIMIXGROUP’s cutting-edge automated production lines enable plant operators to maximize their potential, focusing on strategic decision-making rather than manual tasks. This empowerment not only enhances individual performance but also elevates the overall efficiency of the plant.

Resource Optimization: Reducing Dependency, Maximizing Sustainability

Automation in mobile asphalt mixing plants (передвижные асфальтные заводы цены недорого) significantly reduces human dependency, leading to several benefits. Firstly, it alleviates the burden of labor shortages, enabling plants to operate efficiently even with a smaller workforce.

Moreover, the precision and consistency achieved through automation minimize material wastage, thereby optimizing resource utilization and contributing to a more sustainable production process.

AIMIXGROUP’s dedication to incorporating automated production lines in their mobile asphalt mixing plants exemplifies their commitment to resource optimization and eco-friendly practices.

Unleashing Potential: Ensuring Quality Control with Precision

Automation brings forth a new era of quality control in mobile asphalt mixing plants. The precision and consistency achieved through automated processes ensure that each asphalt mixture adheres to strict quality standards.

Gone are the days of manual sampling and testing; automation enables real-time data analysis, identifying any deviations and enabling timely corrective measures.

AIMIXGROUP’s mobile asphalt mixing plants (передвижной асфальтобетонный завод Китай для продажи в России), equipped with cutting-edge automated production lines, exemplify the company’s dedication to delivering top-notch quality to every project.

Innovating for the Future: Sustainability as a Driving Force

The impact of automated production lines extends beyond immediate benefits. By minimizing human errors, reducing material wastage, and enhancing efficiency, these innovations pave the way for a more sustainable future.

In conclusion, the integration of automated production lines in mobile asphalt mixing plants revolutionizes the road construction industry. AIMIXGROUP’s expertise as a seasoned asphalt equipment manufacturer and distributor is instrumental in driving this transformation. With their innovative approach and dedication to sustainability, AIMIXGROUP (Узнать Компанию AIMIXGROUP больше) sets the standard for excellence in the world of mobile asphalt mixing plants.

Key Considerations Before Installing an Asphalt Mixing Plant

The installation of an asphalt mixing plant is a significant investment and requires careful planning and consideration. Asphalt mixing plants play a crucial role in road construction, offering the capability to produce high-quality asphalt mixes efficiently. However, before embarking on the installation process, there are several essential factors that must be taken into account to ensure a successful and efficient operation.

Site Selection and Preparation

Selecting the right location for the asphalt mixing plant amp is paramount to its long-term success. A level and stable ground with good drainage capabilities is essential. Additionally, the site should be located away from residential areas and sensitive environments to minimize noise and emissions impact. Adequate space for raw material storage, aggregate handling, and finished product storage should also be considered during the site preparation phase.

Local Regulations and Permits

Before commencing the installation process, it is crucial to research and comply with all local regulations and obtain the necessary permits and approvals. Environmental, zoning, safety, and construction permits may be required, and non-compliance can lead to costly delays and legal issues. Engaging with local authorities and stakeholders is essential to ensure a smooth and trouble-free installation process.

Environmental Impact Assessment

An environmental impact assessment (EIA) should be conducted to evaluate the potential impact of the asphalt mixing plant on the surrounding environment. This assessment helps identify possible mitigation measures and ensures compliance with environmental standards. Measures such as dust control systems and noise reduction techniques should be implemented to minimize the plant’s environmental footprint.

Quality of Materials and Equipment

Investing in high-quality materials and equipment is critical for the reliable and efficient operation of the jual amp asphalt mixing plant. Ensure that the plant components, including the mixer, storage silos, conveyors, and control systems, are sourced from reputable manufacturers. Quality components contribute to increased productivity, reduced downtime, and better overall performance of the plant.

Skilled Workforce and Training

Asphalt mixing plant installation and operation require skilled personnel. Prioritize hiring experienced technicians, engineers, and operators who are well-versed in the intricacies of the equipment. Providing comprehensive training to the workforce ensures safe and proficient plant operation, maximizing productivity while minimizing accidents and errors.

Safety Measures

Safety should be a top priority throughout the installation process. Implementing strict safety measures and guidelines helps prevent accidents and ensures the well-being of all personnel involved. Adequate safety equipment, signage, and training programs should be in place to create a safe working environment.

Future Expansion and Maintenance

Consider the potential for future expansion when planning the layout of the amp mini aspal. Leave ample space for additional equipment and facilities that may be required as production demands increase. Additionally, establish a comprehensive maintenance plan to keep the plant in optimal condition, thereby extending its operational lifespan and maximizing return on investment.

Financial Planning and Budgeting

Installing an asphalt mixing plant is a substantial financial undertaking. Proper financial planning and budgeting are necessary to ensure the availability of funds at each stage of the installation process. Careful cost estimation, contingencies for unexpected expenses, and financing options should be thoroughly evaluated before beginning the installation.

Conclusion

The installation of an asphalt mixing plant demands careful consideration of various factors to ensure its successful operation and longevity. From site selection and preparation to compliance with regulations, harga aspal mixing plant mobile, and from skilled workforce to environmental impact assessment, each aspect plays a pivotal role in the overall success of the project. By addressing these key considerations before installation, asphalt plant owners can lay a solid foundation for a highly efficient, safe, and environmentally-friendly operation.

Top Benefits Of The Portable Concrete Pump

The portable concrete pump allows you to pump concrete right at the job site. The pump is easy to move around and it is a powerful and efficient pump. It pumps out concrete at high pressure so you get the concrete exactly where you need it. This machine is often found at construction sites and other building sites. Read on to learn more about this pump and what you should look for when you are buying one.

Wide Application

This pump can be exported to over 30 countries and it is affordable so you won’t have to worry about the concrete mixer pump price being too high. This pump is very popular around the world and it is found in many construction sites. The pump can be found at road construction sites, mines, underground construction areas and more. Any job site that needs concrete can benefit from the portable pump.

The pump can fit into even the tightest of spaces and it can hold a lot of concrete. The pump has a powerful pumping mechanism that ensures that the concrete is easy to pump into any space. When you don’t have room for a large pump and you need something that you can easily move around from area to area, the portable pump is a great choice. This pump is easy to use and it is even good for the environment.

Environmental Choice

The pump has a special dust collector that prevents any dust from getting out into the environment and it is designed to use small amounts of power which make it affordable and cheap to run. The portable concrete pumper can even be run on a generator if you don’t have access to the correct power.

The small size of the pump makes it the best choice when you need to get into a tight situation with the pump. The pump is light and it is easy to move around. The pump has a low failure rate and it also has a long working life which ensures that the pump will not fail on you. It will work for a long time and it performs well so you don’t have to worry about problems with the pump.

The pump is capable of delivering concrete for long distances and it can even deliver concrete to high buildings. The pump will work continuously and it is very efficient. It can work much faster than any man and it decreases the cost of labor when you use it. More useful information: https://concretemixerwithpump.com/.

Small Ones

The small concrete pump is simple. There is a hopper for the concrete, a pumping system and a hydraulic system. The small concrete mix pump machine can work continuously as long as there is concrete to pump. It will deliver large amounts of concrete to any work site and the pump will help you get everything done.

How Much Do You Know About Boom Pump for Sale in The Market?

Boom pumps have become a staple in the construction industry, revolutionizing the way concrete is poured into high or hard-to-reach areas. They are the superheroes of construction, soaring high above mere mortal pouring methods. If you’re planning to join the concrete pouring party, it’s crucial to familiarize yourself with the world of boom pumps for sale in the market. So, tighten your hard hat and prepare to dive into the exhilarating world of these concrete-delivery wonders.

Understanding Boom Pumps

First things first, what exactly are boom pumps? Well, dear readers, boom pumps are powerful machines designed to make concrete delivery a breeze. They consist of a hydraulic arm, known as the boom, which can extend and maneuver to reach those pesky spots that traditional pouring methods can’t handle. Gone are the days of ladders and buckets, my friends!

Now, let’s delve into the different types of boom pumps available. In one corner, we have the mighty truck-mounted boom pumps, towering over the competition with their unmatched mobility and reach. And in the other corner, we have the agile trailer-mounted boom pumps, ready to strut their stuff in smaller construction sites. Remember, folks, it’s all about choosing the right concrete pump with boom for the job at hand.

Evaluating Boom Pump Features

When you’re on the hunt for a boom pump that will make all your concrete dreams come true, you need to know which features to consider. It’s like picking the perfect companion for your construction adventures. First, let’s talk about boom length and reach. The longer the boom, the higher and farther it can reach. It’s like having an elastic arm, stretching to places mere mortals can only dream of.

Next up, we have pump capacity and pressure. These are the powerhouse muscles of the boom pump. The higher the capacity, the more concrete it can deliver in a single pump. And pressure? Well, that’s all about how forcefully it can squirt that concrete goodness. We’re talking about serious hydraulic action here.

But wait, there’s more! Let’s not forget about the additional features that can enhance your boom pump experience. We’re talking remote control, outriggers, and stabilizers. With a remote control in hand, you’ll feel like a construction maestro, conducting your concrete orchestra from a safe distance. And those outriggers and stabilizers? They keep your boom pump steady and balanced, like a tightrope walker defying gravity. Get more pump features here: CONCRETEMIXERWITHPUMP.COM

Researching the Market

Now that you’ve familiarized yourself with the ins and outs of boom pumps, it’s time to venture into the market. Fear not, dear readers, for the internet is your trusty sidekick in this quest. Online platforms and marketplaces await your arrival, offering a smorgasbord of boom pumps for your perusal. Compare prices, specifications, and read customer reviews as if you’re searching for the holy grail of concrete delivery.

But don’t stop there! Pay a visit to local dealers and suppliers. Get up close and personal with these concrete giants. Interact with the experts, who will guide you through the labyrinth of boom pumps. Ask questions, touch the equipment (with permission, of course), and get a feel for the powerful machinery that will soon become your construction companion.

Comparing Prices and Quality

Ah, the eternal struggle of finding the perfect balance between price and quality. When it comes to boom pumps, my dear readers, it’s no different. Price tags can vary depending on a multitude of factors. Brand reputation, quality of materials and components, and the size and features of the concrete pump mixer for sale all play a role. Consider these factors, and you’ll be well on your way to making an informed decision.

But here’s a word of wisdom for you: don’t get blinded by the allure of low prices alone. In the world of boom pumps, quality is king. A well-built and reliable boom pump may cost a bit more upfront, but it will save you from future headaches and repair costs. Think long-term value, my friends, and you shall be rewarded with smooth concrete pouring and construction bliss.

Conclusion

Congratulations, my dear readers! You have successfully ventured into the intriguing realm of boom pumps for sale in the market. Armed with knowledge and a healthy dose of sarcasm, you’re now equipped to make informed decisions when choosing a boom pump for your construction endeavors. Remember, it’s all about understanding truck mounted concrete pump types, evaluating features, and researching thoroughly. So go forth and conquer the construction world, one concrete pour at a time!

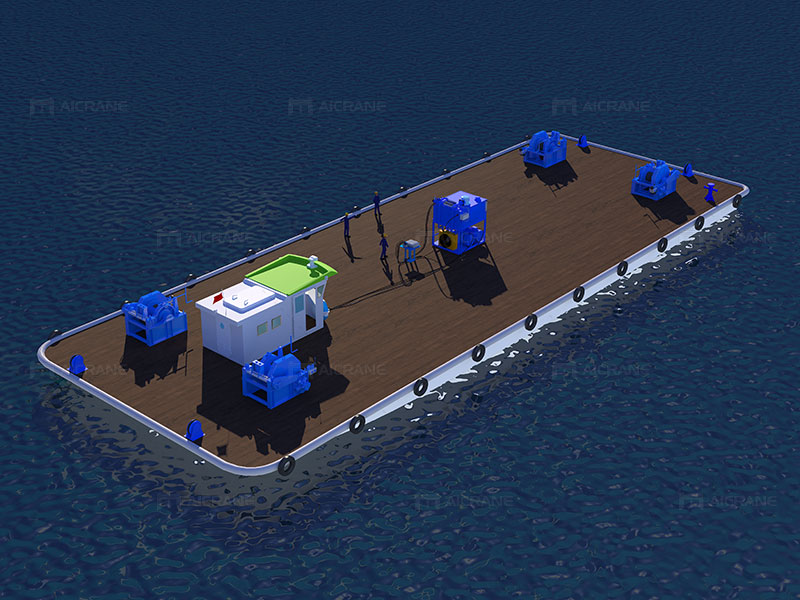

Diverse Uses and Benefits of Multi-Point Mooring Winch System

Multi-point mooring winch systems are advanced maritime tools that provide stability and secure positioning for vessels, floating structures, and offshore installations. These winch systems play a crucial role in various industries, offering numerous benefits such as enhanced safety, operational efficiency, and improved maneuverability. In this article, we explore the diverse uses and significant advantages of multi-point mooring winch systems, highlighting their importance in maritime operations worldwide.

Offshore Oil and Gas Industry:

The offshore oil and gas industry heavily relies on multi-point mooring winch systems to maintain the position and stability of drilling rigs, production platforms, and floating production storage and offloading (FPSO) vessels. By using multiple anchor points and winches, these systems allow for precise positioning, reducing the risk of drifting or damage caused by strong currents or harsh weather conditions. This enhances safety for personnel and equipment while facilitating efficient operations and maximizing production output.

Floating Wind Farms:

As renewable energy gains momentum globally, floating wind farms are emerging as a viable solution for harnessing wind power in deep waters. Multi-point mooring winch systems are integral to the installation and maintenance of these wind farms. They enable precise positioning and orientation of the floating turbines, ensuring optimal wind capture and minimizing the impact of waves and currents. By utilizing multi-point mooring, these systems enhance the stability and reliability of floating wind farms, enabling the generation of clean energy.

Marine Research and Exploration:

Multi-point mooring winch systems are essential tools in marine research and exploration operations. They facilitate the deployment and retrieval of scientific instruments, remotely operated vehicles (ROVs), and autonomous underwater vehicles (AUVs). These mooring winches ensure accurate positioning, enabling scientists and researchers to conduct surveys, collect data, and explore the ocean depths effectively. The stability provided by multi-point mooring enhances the quality and safety of marine research initiatives.

Disaster Response and Emergency Operations:

During emergency situations, such as natural disasters or oil spills, multi-point mooring winch systems offer critical support for response and recovery efforts. They enable the rapid deployment and positioning of floating equipment, emergency vessels, and oil containment booms. The winches provide stability and control, facilitating efficient and coordinated operations in challenging environments. The versatility of multi-point mooring systems makes them valuable assets in disaster response and emergency management scenarios.

Shipyard and Marine Construction:

Multi-point mooring winch systems find application in shipyard and marine construction projects. They assist in the docking and undocking of vessels, enabling precise maneuvering and minimizing the risk of collisions or accidents. These winch systems are also utilized during the construction of offshore structures, such as floating docks, pontoons, and jetties, ensuring accurate positioning and stability during the construction process. The use of multi-point mooring winches enhances safety and productivity in marine construction activities.

Benefits of Multi-Point Mooring Winch Systems:

- Enhanced Safety: Multi-point mooring winch systems provide stability and precise positioning, reducing the risk of accidents, collisions, and equipment damage.

- Operational Efficiency: These systems allow for quick deployment, retrieval, and repositioning of vessels and equipment, maximizing operational efficiency and minimizing downtime.

- Versatility: Multi-point mooring winch systems can be adapted to various applications and environments, offering flexibility and versatility in different industries.

- Environmental Resilience: The use of multi-point mooring minimizes the impact of waves, currents, and adverse weather conditions, ensuring the stability and resilience of offshore installations.

- Cost Savings: By enabling efficient operations and reducing downtime, these positioning winch systems contribute to cost savings in terms of time, resources, and maintenance.

Conclusion:

Multi-point mooring winch systems have become indispensable tools in numerous industries, offering diverse uses and significant benefits. From offshore oil and gas operations to renewable energy projects, marine research to emergency response efforts, these winches provide stability, control, and enhanced safety. With their versatility and operational efficiency, multi-point mooring winch systems continue to drive advancements in maritime operations, supporting industries and promoting sustainable practices in a dynamic and challenging marine environment.