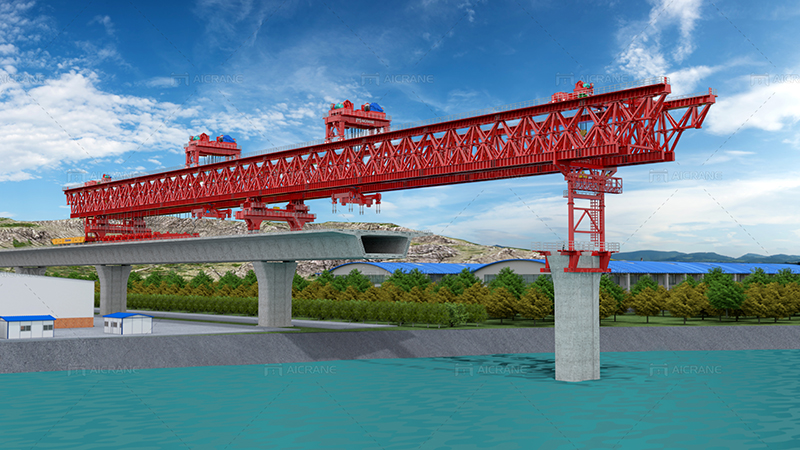

How Does a Bridge Girder Launching Gantry Crane Work?

In the world of civil engineering, the construction of bridges is a complex and awe-inspiring feat that requires precision, innovation, and advanced machinery. Among the many specialized tools used in bridge construction, the Bridge Girder Launching Gantry Crane stands out as a key player. This remarkable piece of engineering equipment plays a crucial role in efficiently and safely placing bridge girders, contributing to the seamless assembly of these colossal structures. In this article, we will delve into the intricacies of how a Bridge Girder Launching Gantry Crane operates, exploring its design, functions, and significance in modern bridge construction.

Understanding the Basics of Launching Gantry Crane:

Before we unravel the inner workings of a Bridge Girder Launching Gantry Crane, it is essential to grasp the fundamentals of bridge construction. Bridge girders, the horizontal supports of a bridge, come in various shapes and sizes depending on the type of bridge being built. These girders must be carefully positioned and secured to form the skeleton of the bridge before other components, such as the deck and railing, can be added.

This is where the Bridge Girder Launching Gantry Crane steps in. Essentially, it is a specialized crane designed for the precise installation of bridge girders. Unlike traditional cranes, the launching gantry crane operates on a system of tracks or rails, allowing it to move horizontally along the length of the bridge during construction.

Key Components and Design of Launching Gantry:

A typical Bridge Girder Launching Gantry Crane consists of several key components, each playing a crucial role in the overall functionality of the system.

Main Girder: The main girder is the primary structural component of the crane, spanning the width of the bridge. It provides the necessary support for the other components and ensures stability during the girder placement process.

Launching Nose: This is the front part of the crane that extends beyond the main girder. The launching nose is equipped with mechanisms for lifting, lowering, and precisely placing the bridge girders.

Lifting Mechanism: The lifting mechanism is responsible for hoisting the bridge girders from the ground and positioning them accurately in place. This mechanism is often equipped with advanced control systems to ensure precision during the lifting and lowering process.

Horizontal Movement System: Unlike conventional cranes, a Bridge Girder Launching Gantry Crane is designed to move horizontally along the length of the bridge. This is achieved through a sophisticated system of tracks or rails that guide the crane to the desired location.

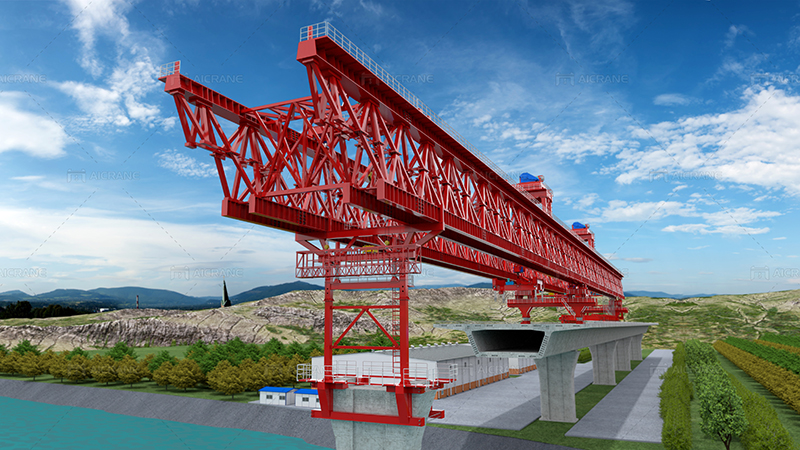

Operational Process of Launching Gantry Crane:

The operation of a Bridge Girder Launching Gantry Crane can be broken down into several key steps, highlighting the precision and coordination required for successful bridge construction.

Positioning: The crane is initially positioned at one end of the bridge using its horizontal movement system. This allows it to access different sections of the bridge during the construction process.

Girder Loading: The lifting mechanism is engaged to hoist a bridge girder from the ground. Advanced sensors and controls ensure that the girder is securely attached and properly aligned for placement.

Horizontal Movement: The crane moves horizontally along the bridge, carrying the lifted girder to its designated position. This horizontal movement is controlled with precision to align the girder accurately.

Girder Placement: Once in position, the crane’s launching nose delicately lowers the bridge girder into place. This step requires meticulous control to ensure that the girder aligns perfectly with the existing structure.

Repeat Process: The entire process is repeated for each successive girder until the bridge’s skeleton is complete. The bridge construction crane continues to move along the bridge, systematically placing girders with remarkable accuracy.

Significance in Bridge Construction:

The Bridge Girder Launching Gantry Crane plays a pivotal role in modern bridge construction for several reasons:

Efficiency: The use of a launching gantry crane significantly speeds up the construction process by allowing for the rapid and precise placement of bridge girders.

Safety: The advanced control systems and automated features enhance safety by reducing the risk of human error during girder placement.

Adaptability: These cranes can be customized to accommodate various bridge designs and specifications, making them adaptable to a wide range of construction projects.

Cost-effectiveness: While the initial investment in a Bridge Girder Launching Gantry Crane may be substantial, the efficiency and speed it brings to the construction process can result in overall cost savings.

Conclusion:

In the realm of civil engineering, the Bridge Girder Launching Gantry Crane stands as a testament to human ingenuity and innovation. Its ability to lift, move, and precisely place bridge girders has revolutionized the construction of bridges, making the process more efficient, safe, and cost-effective. As technology continues to advance, we can expect further refinements and enhancements in the design and functionality of these remarkable machines, contributing to the creation of even more ambitious and awe-inspiring bridges around the world. For more info, visit https://steelmillcranes.com/

Why Your Next Batching Plant Should Be Eco-Friendly

In today’s world, environmental conservation is not just a moral duty but a crucial requirement. The construction industry, known for its significant environmental impact, is now witnessing a pivotal shift toward sustainability. Central to this transformation is the concrete batching plant, a staple in construction projects. This article delves into how adopting environmentally friendly batching plants can reduce ecological footprints and why customers should be part of this green revolution.

The Urgency to Adopt Eco-Friendly Practices in Concrete Production

Concrete production is resource-intensive and contributes to various forms of pollution. However, innovation and technology offer a pathway to mitigate these environmental harms. Transitioning to eco-friendly concrete batching plants is not merely a trend but an essential step for the future of construction.

The Environmental Impact of Traditional Batching Plants

Traditional concrete batching plants are major sources of CO2 emissions, dust, and noise pollution. They consume vast amounts of water and energy, exacerbating their ecological footprint. Recognizing these impacts is the first step towards embracing sustainable alternatives.

Benefits of Eco-Friendly Concrete Batching Plants

Investing in an environmentally friendly batching plant brings multifaceted advantages. Not only does it contribute to the planet’s well-being, but it also enhances operational efficiency and cost-effectiveness in the long run.

Reduced Carbon Footprint

Eco-friendly batching plants are designed to lower CO2 emissions through energy-efficient operations. By integrating renewable energy sources and optimizing production processes, the environmentally friendly concrete mixing plant makes a substantial difference in reducing the carbon footprint of construction projects.

Less Resource Consumption

Advanced water recycling systems and waste management practices in modern batching plants ensure minimal resource wastage. This responsible use of resources not only protects the environment but also translates to savings for businesses.

Compliance with Environmental Regulations

With stricter environmental regulations coming into play, investing in an eco-friendly batching plant ensures compliance and avoids potential penalties. It positions companies as responsible entities committed to sustainable development.

Choosing the Right Eco-Friendly Concrete Batching Plant

Deciding on the most suitable eco-friendly batching plant requires careful consideration of several factors, including technological features, capacity, and after-sales support. Potential customers should seek out concrete batch plants manufacturers who prioritize sustainability alongside quality and efficiency.

Key Features to Look For

When selecting an environmentally friendly batching plant, look for energy-saving designs, advanced dust control systems, and efficient water recycling features. These elements are indicative of a genuinely eco-conscious manufacturing approach.

The Role of Innovation and Technology

Technology plays a critical role in enhancing the eco-friendliness of batching plants. Cutting-edge solutions like automated control systems and AI-driven efficiency optimizations are paving the way for greener construction practices.

Making the Sustainable Choice: A Call to Action

The move towards environmentally friendly concrete batching plants represents a win-win for both the planet and businesses. It’s a testament to the industry’s ability to innovate and adapt in response to environmental challenges. By choosing the concrete mixture plant, customers not only contribute to a healthier planet but also invest in the long-term sustainability of their operations. Now is the time to embrace this green revolution in concrete production and lead the charge toward a more sustainable future.

Why Customers Should Care

Every choice made in the construction process has environmental implications. Opting for an eco-friendly batching plant is a powerful statement of commitment to sustainability. It reflects a forward-thinking mindset that values efficiency, compliance, and corporate responsibility.

The Competitive Edge

Beyond the environmental benefits, adopting green technologies in concrete production offers a competitive advantage. It enhances a company’s reputation, opens up new business opportunities, and attracts customers who prioritize eco-conscious products and services.

Conclusion: Paving the Way for a Greener Future

The transition to environmentally friendly concrete batching plants is not just a possibility but a necessity. As we forge ahead, the construction industry’s role in environmental stewardship becomes increasingly significant. By making informed choices and investing in eco-friendly solutions, we can significantly reduce the ecological impact of construction activities. Together, let’s build a sustainable future, one eco-friendly batching plant at a time.

The journey towards sustainability is a shared responsibility. Eco-friendly batching plants offer a concrete step towards a greener planet. Click here to learn more about concrete batching plant price list. Let’s embrace this opportunity and lead by example in the pursuit of environmental excellence. The time to act is now.

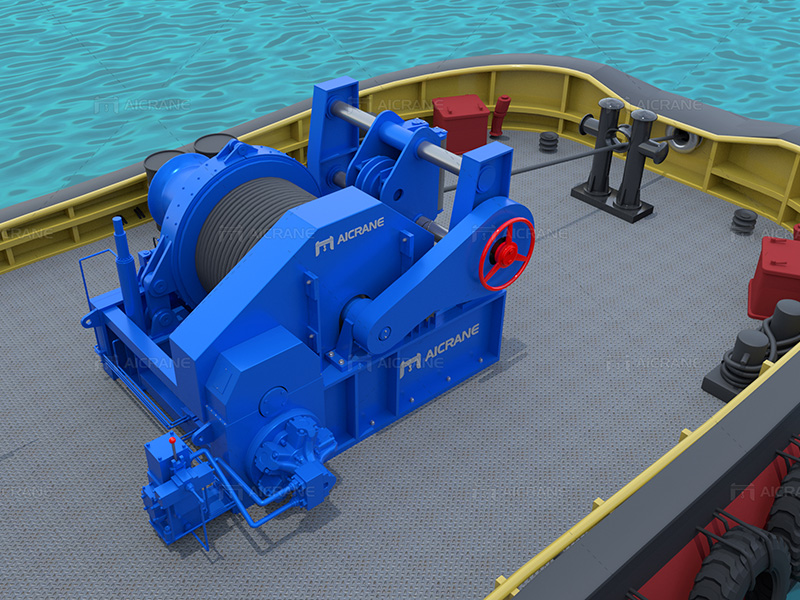

How the Hydraulic System of a Tugger Winch Works

Hydraulic systems play a pivotal role in the operation of various machinery, including tugger winches utilized in maritime settings. These winches are crucial for tasks ranging from towing to mooring operations, requiring robust and efficient mechanisms to handle heavy loads. Among the diverse range of winch systems available, hydraulic tugger winches stand out for their reliability and power. In this article, we delve into the intricate workings of the hydraulic system that drives these indispensable maritime tools.

The Basics of Hydraulic Tugger Winches:

Before delving into the hydraulic system’s mechanics, it’s essential to grasp the fundamental components and functionalities of a hydraulic tugger winch. Tugger winches are primarily designed to handle the pulling or lifting of heavy loads on ships, rigs, or offshore platforms. They consist of a drum or spool around which a cable or rope is wound, connected to a power source for operation.

Understanding the Hydraulic System:

At the heart of a hydraulic tugger winch lies its hydraulic system, which provides the power necessary for its operation. This system comprises several key components working in tandem to convert hydraulic energy into mechanical force.

Hydraulic Pump: The hydraulic pump serves as the heart of the system, responsible for generating hydraulic pressure. Typically powered by an electric motor or an internal combustion engine, the pump pressurizes hydraulic fluid, usually oil, and delivers it to the rest of the system.

Hydraulic Fluid: Hydraulic fluid serves as the medium through which power is transmitted within the hydraulic system. It must possess specific characteristics such as viscosity, lubricity, and stability to ensure optimal performance and longevity of the system.

Control Valves: Control valves regulate the flow and direction of hydraulic fluid within the system. These valves can be manually operated or equipped with solenoids for remote control, allowing operators to precisely adjust the speed and direction of winch operation.

Hydraulic Motor: The hydraulic motor converts hydraulic energy into mechanical energy to drive the winch’s drum or spool. It receives pressurized hydraulic fluid from the pump and utilizes it to rotate a shaft, thereby imparting motion to the winch mechanism.

Cylinder: In some hydraulic tugger winches, a hydraulic cylinder may be employed to control specific functions such as tensioning or locking of the cable. The cylinder utilizes hydraulic pressure to extend or retract a piston, thereby exerting force on the connected components.

Working Principle:

The operation of a hydraulic tugger winch is initiated when the hydraulic pump begins pressurizing hydraulic fluid. This pressurized fluid is directed through control valves to the hydraulic motor, causing it to rotate. As the motor turns, it drives the winch’s drum or spool, thereby winding or unwinding the cable connected to the load.

The direction of winch operation, whether pulling or releasing the cable, is controlled by manipulating the flow of hydraulic fluid through the control valves. Additionally, the speed of the tugger winch can be adjusted by varying the flow rate of hydraulic fluid to the motor.

Benefits of Hydraulic Tugger Winches:

Hydraulic tugger winches offer several advantages over their electric or manual counterparts. Firstly, they provide high levels of power and torque, making them well-suited for handling heavy loads in demanding maritime environments. Additionally, hydraulic systems are known for their efficiency and reliability, requiring minimal maintenance and offering long service life.

Moreover, hydraulic tugger winches offer precise control over load handling operations, allowing operators to adjust speed and direction with ease. This level of control is essential for tasks such as towing, mooring, and positioning of vessels or equipment.

Conclusion:

In conclusion, the hydraulic system of a tugger winch forms the backbone of its operation, enabling the efficient handling of heavy loads in maritime applications. By understanding the intricacies of this system, operators can harness its power and versatility to enhance productivity and safety in maritime operations. With ongoing advancements in hydraulic technology, the future looks promising for hydraulic tugger winches, ensuring they remain indispensable assets in the maritime industry. To learn more about winches, visit https://winchmachines.com/

How Do Small Self Loader Concrete Mixers Compare In Terms Of Productivity And Output To Larger Stationary Mixers?

Small self loader concrete mixers and larger stationary mixers serve distinct roles in construction projects, each with its own set of advantages and limitations. Understanding how these two types of mixers compare in terms of productivity and output is crucial for contractors and construction professionals.

Overview of Small Self Loader Concrete Mixers

Small self loader concrete mixers are compact machines designed for mixing and transporting concrete on construction sites with limited space. They typically feature a self-loading mechanism, allowing operators to load materials directly into the mixer without the need for additional equipment. The Small Self Loader Concrete Mixer is prized for their maneuverability and versatility, making them ideal for small to medium-sized construction projects.

Overview of Larger Stationary Mixers

Larger stationary mixers, on the other hand, are heavy-duty machines designed for high-volume concrete production. These mixers are typically installed at centralized batching plants or large-scale construction sites. They feature a fixed drum or container where materials are batched, mixed, and discharged. Larger stationary mixers are capable of producing large quantities of concrete consistently and efficiently, making them suitable for large construction projects.

Productivity Comparison

Factors Influencing Productivity

Several factors influence the productivity of concrete mixers, regardless of size. These factors include the mixing capacity, mixing speed, loading and unloading times, and overall efficiency of the machine. Additionally, the skill and experience of the operator play a significant role in maximizing productivity. View more details about mixers here: https://aimixglobal.com/self-loading-concrete-mixer-truck/.

Efficiency of Small Self Loader Mixers

While small self loader mixers may have smaller mixing capacities compared to larger stationary mixers, they offer advantages in terms of on-site efficiency and flexibility. These compact self loading mixers can maneuver in tight spaces and deliver concrete directly to the point of placement, reducing the need for additional handling and transportation. Additionally, self-loading features allow operators to batch and mix concrete as needed, minimizing waste and downtime.

Output Comparison

Capacity Differences Between Small and Large Mixers

One of the most significant differences between small self loader mixers and larger stationary mixers is their capacity for concrete production. Larger stationary mixers typically have higher mixing capacities, allowing them to produce larger volumes of concrete in a single batch. In contrast, small self loading cement mixer for sale has limited capacities but excel in producing smaller batches of concrete quickly and efficiently.

Quality and Consistency of Output

While larger stationary mixers may offer higher production capacities, small self loader mixers are known for their ability to produce high-quality concrete consistently. These compact mixers utilize advanced mixing technology and control systems to ensure uniform mixing and proper concrete consistency. Additionally, self-loading features enable operators to adjust mix designs on-site, optimizing the quality of the final product.

Heavy Lifting Made Easy: Unraveling the Benefits of 30-Ton Gantry Cranes

In the dynamic landscape of heavy industry, where efficiency and precision are paramount, the 30-ton gantry crane stands tall as a powerhouse for lifting and moving substantial loads. This robust machinery, also known as a double girder gantry crane, has become indispensable in various sectors. In this exploration, we unravel the myriad benefits of 30-ton gantry cranes, shedding light on why industries are increasingly turning to these heavy lifters.

Exceptional Lifting Capacity

At the heart of the 30-ton gantry crane’s appeal is its remarkable lifting capacity. Designed with a robust double girder structure, these cranes can effortlessly hoist and transport heavy loads up to 30 tons, making them a go-to choice for industries dealing with substantial materials and equipment. This exceptional lifting capacity translates to increased efficiency in various applications, from manufacturing to construction and beyond.

Versatility in Applications

One of the key advantages of the 30-ton gantry crane is its versatility. These cranes find applications across a spectrum of industries, adapting seamlessly to diverse work environments. Whether it’s lifting heavy machinery in manufacturing plants, aiding in construction projects, or facilitating material handling in warehouses, the versatility of the 30-ton gantry crane(Козловой кран 30 тонн) makes it a flexible and reliable solution for numerous tasks.

Precision and Control

The double girder design not only contributes to the crane’s lifting capacity but also enhances precision and control during operations. The additional support provided by the dual beams ensures stability, allowing for precise movements and positioning of loads. This level of control is particularly crucial in industries where delicate handling of heavy materials is essential, promoting both safety and operational efficiency.

Durability and Longevity

Investing in a 30-ton gantry crane represents a commitment to durability and longevity. These cranes are engineered with high-quality materials, ensuring robustness in the face of heavy-duty operations. The double girder configuration adds an extra layer of structural integrity, contributing to the crane’s ability(Козловой кран грузоподъемность) to withstand the rigors of daily use. When maintained properly, these cranes become enduring assets for industries, providing reliable performance over an extended lifespan.

Ease of Maintenance

Maintenance is a critical aspect of any heavy machinery, and 30-ton gantry cranes are designed with ease of maintenance in mind. Accessible components and straightforward inspection points simplify routine checks, allowing for proactive maintenance that minimizes downtime. Choosing a reputable gantry crane manufacturer ensures not only initial quality but also ongoing support and availability of spare parts for efficient maintenance.

Considerations in Purchasing Gantry Cranes

When considering the purchase of a 30-ton gantry crane, it’s essential to carefully evaluate various factors. Selecting a reliable gantry crane manufacturer(Aicrane) is the first step. Look for manufacturers with a proven track record, quality certifications, and a reputation for delivering cranes that meet industry standards. Additionally, consider the specific requirements of your industry, including span and height requirements, operating environment, and safety features.

Choosing the Right Gantry Crane Manufacturer

The success of a 30-ton gantry crane largely hinges on the choice of the manufacturer. Reputable manufacturers prioritize engineering excellence, adhere to safety standards, and offer customization options to meet specific industry needs. Researching customer reviews, examining the manufacturer’s portfolio, and seeking recommendations can aid in making an informed decision.

In conclusion, the benefits of 30-ton gantry cranes extend far beyond their impressive lifting capacity. These double girder gantry cranes(Двухбалочный козловой кран) bring versatility, precision, durability, and ease of maintenance to industries engaged in heavy lifting operations. As businesses explore options for enhancing their material handling capabilities, the 30-ton gantry crane emerges as a reliable and efficient solution, making heavy lifting seem remarkably easy. When guided by thoughtful consideration in the purchasing process, including choosing the right gantry crane manufacturer, industries can unlock the full potential of these heavy lifters in their operations.

Moving with Precision: The Innovation of Rubber Gantry Crane Technology

In the bustling landscape of modern industry, precision and efficiency are paramount. One of the most pivotal innovations driving this efficiency is the emergence of rubber gantry crane technology. These versatile machines have revolutionized material handling operations, offering a blend of mobility, precision, and adaptability that traditional crane systems cannot match. In this article, we delve into the innovation of rubber gantry crane technology, exploring its capabilities, applications, and impact on various industries.

Evolution of Rubber Gantry Crane Technology

Rubber gantry cranes represent a significant evolution in material handling technology. Unlike traditional gantry cranes that rely on fixed rail systems, rubber gantry cranes are equipped with rubber tires, allowing them to move freely within a designated area without the need for extensive infrastructure modifications. This mobility enhances operational flexibility, enabling seamless navigation around facilities, warehouses, and storage yards.

Precision Control Systems

At the heart of rubber gantry crane technology lies advanced precision control systems. These systems integrate cutting-edge automation technology, enabling operators to execute lifting, stacking, and transportation tasks with unparalleled accuracy and efficiency. From remote control interfaces to automated stacking algorithms, rubber gantry cranes equipment empower operators to streamline material handling operations while minimizing errors and downtime.

Versatility in Application

Rubber gantry cranes find application across a diverse range of industries, each with its unique set of challenges and requirements. In ports and terminals, these cranes play a pivotal role in loading and unloading cargo containers from ships, transporting them across terminal yards, and facilitating seamless logistics operations. Their ability to navigate congested dock areas and adapt to changing tide levels makes them indispensable assets in maritime environments.

In manufacturing facilities and distribution centers, rubber gantry cranes streamline material handling processes, enabling efficient storage, retrieval, and distribution of goods. Their versatility allows them to handle a wide variety of cargo types, from bulk commodities to oversized machinery components, with precision and ease. Moreover, their ability to operate indoors and outdoors makes them ideal for facilities with diverse operational requirements.

Enhanced Safety Features

Safety is a paramount concern in industrial environments, and rubber gantry cranes are equipped with a range of advanced safety features to mitigate risks and ensure the well-being of personnel and equipment. Collision detection systems, anti-sway technology, and automatic overload protection mechanisms are just a few examples of the safety features integrated into modern rubber gantry crane systems. These features not only enhance workplace safety but also protect valuable assets and minimize the risk of costly accidents and downtime.

Environmental Considerations

In an era marked by increasing environmental awareness, rubber gantry cranes offer eco-friendly solutions for material handling operations. Unlike diesel-powered cranes that emit harmful pollutants, many rubber gantry cranes are equipped with electric drivetrains, significantly reducing carbon emissions and minimizing environmental impact. Additionally, their efficient energy usage and regenerative braking systems further contribute to sustainability efforts, making them preferred choices for companies committed to reducing their carbon footprint and operating sustainably.

Advancing Industry Through Innovation

In conclusion, the innovation of rubber gantry crane technology represents a significant leap forward in material handling capabilities. With their mobility, precision control systems, versatility, and enhanced safety features, rubber gantry cranes are transforming the way industries handle and transport goods. From ports and terminals to manufacturing facilities and distribution centers, these innovative machines are driving efficiency, productivity, and sustainability in industrial operations around the world. Straddle crane is also a kind of rubber tyred gantry crane, used for handling heavy loads.

As technology continues to evolve, so too will the capabilities of rubber gantry cranes. With ongoing advancements in automation, connectivity, and energy efficiency, the future holds boundless opportunities for further innovation and optimization in material handling technology. Embracing the innovation of rubber gantry crane technology, industries can navigate the complexities of modern supply chains with precision, agility, and confidence, paving the way for a more efficient and sustainable future.

How Is The Concrete Mixing Process Carried Out In A Self-Loading Rough Terrain Concrete Mixer

In the world of construction, the dance of concrete mixing is orchestrated by self-loading rough terrain concrete mixers. These robust machines embody a unique prowess, akin to a maestro directing a symphony. Let’s delve into the intricacies of how this artistic process unfolds, turning raw materials into the building blocks of civilization.

The Ingenious Mechanism Behind Self-Loading Rough Terrain Mixers

Self-loading rough terrain concrete mixers are not mere machines; they are artisans of construction sites. Their ingenious design involves a combination of mobility and autonomy, much like a skilled painter navigating a canvas. The robust chassis and four-wheel-drive capabilities make these mixers agile in challenging terrains, allowing them to bring the art of concrete mixing to remote locations.

The Choreography of Material Loading

In the concrete mixing ballet, the first act is the choreography of material loading. Raw ingredients, including cement, aggregates, and water, are precisely measured and loaded into the mixer’s drum. It’s a meticulous dance, reminiscent of a painter selecting the right colors for a masterpiece. The automated loading system ensures accuracy, setting the stage for a harmonious blend of materials.

The Symphony of Mixing and Agitation

As the ingredients take their places within the drum, the symphony of mixing and agitation commences. This is where the self loading rough terrain mixer truly shines—an orchestra of rotating blades ensures a thorough and uniform blend. The mixer’s ability to navigate rough terrains mirrors the graceful movements of a dancer, effortlessly combining materials to create a homogenous concrete mix.

Precision Pouring: A Balletic Finale

The culmination of the concrete mixing performance is the precision pouring—a balletic finale where the mixed concrete is discharged with accuracy. The mixer’s maneuverability allows it to pour the concrete exactly where needed, akin to an artist delicately applying the finishing touches to a canvas. This controlled discharge ensures that the concrete is placed with precision, minimizing waste and maximizing efficiency.

The Art of Automation in Concrete Mixing

Beyond its physical prowess, the self-loading rough terrain concrete mixer is a testament to the art of automation in concrete mixing. It operates with a level of autonomy that transforms the construction site into a canvas waiting for the strokes of efficiency and precision. Check its mixing process on this page: https://concretemixerwithpump.com/self-loading-transit-mixer/.

Sensorial Mastery: Ensuring Proportions and Quality

In the art of concrete mixing, proportions and quality are paramount. Self-loading mixers boast sensorial mastery, utilizing advanced sensors to monitor and control the mixing process. This digital precision ensures that the ratios of materials are maintained, guaranteeing a concrete mix that meets the highest standards. It’s a technological ballet where sensors dance to the rhythm of perfection.

Operational Choreography: Minimizing Human Intervention

The operational choreography of self-loading mixers involves minimizing human intervention without compromising quality. Much like a skilled director orchestrating a play, these mixers streamline processes, reducing the need for manual labor. Automation takes center stage, allowing construction teams to focus on higher-order tasks while the mixer continues its artistry.

Efficiency Unveiled: The Grandeur of Time and Resource Management

In the grand theatre of construction, time and resource management take center stage. The self loading concrete mixer for sale UK unveils a grandeur of efficiency that rivals the most meticulously orchestrated productions.

Time-Efficient Maneuvering: Navigating Construction Realms

Time efficiency unfolds as these mixers navigate construction realms with agility. Their ability to move swiftly through rough terrains and reach remote locations expedites the concrete mixing process. It’s a time-saving ballet, where every movement contributes to the swift completion of projects, aligning with the demands of tight construction schedules.

Resource Optimization: Maximizing the Symphony of Materials

Resource optimization takes center stage as self-loading mixers maximize the symphony of materials. By precisely measuring and combining raw ingredients, these mixers minimize material waste. It’s a virtuoso performance where the efficient use of resources not only enhances sustainability but also contributes to cost-effectiveness.

In the world of construction, where every project is a unique canvas, self loading concrete mixer for sale in USA emerges as artists of efficiency, precision, and autonomy. Their choreography of material loading, symphony of mixing, and precision pouring reflect the artistry that transforms raw materials into the structural masterpieces that shape our world.

Project Precision: Decoding Boom Pump vs Mixing Pump Choices

Precision in construction projects hinges on making informed choices, especially when it comes to selecting between boom pumps and mixing pumps. Each plays a distinct role in the concrete delivery process, and understanding their nuances is pivotal for project success.

The Concrete Dynamics of Boom Pumps

1. Advanced Reach and Flexibility

The first aspect to consider when evaluating boom pumps is their unparalleled reach and flexibility. These hydraulic marvels are equipped with extendable arms, capable of reaching considerable heights and navigating complex construction sites with ease. The ability to precisely place concrete in challenging locations is a boon for projects with intricate designs or constrained spaces.

2. Efficient Pouring for High-Rise Structures

Boom pumps shine in scenarios where verticality is paramount. For high-rise structures, the strategic deployment of a boom pump ensures a continuous, controlled pour, minimizing the risk of material segregation and enhancing the structural integrity of the final construction. This efficiency can significantly accelerate project timelines.

3. Tailored for Large-Scale Projects

Large-scale construction projects demand not only quantity but also precision in concrete placement. Boom pumps excel in delivering substantial volumes of concrete swiftly, making them indispensable for expansive ventures like commercial buildings, bridges, or infrastructure projects. Their adaptability to varying project scales adds versatility, making them a preferred choice.

Mixing Pumps: The Blend of Consistency and Control

1. Homogeneous Mixes for Quality Assurance

When the emphasis is on achieving a consistent mix of concrete, mixing pumps take the spotlight. The concrete mixing pump boasts integrated mixers that ensure a homogeneous blend of materials, crucial for projects demanding a high degree of quality assurance. The controlled mixing process minimizes material waste and enhances overall efficiency.

2. On-Site Mixing for Real-Time Adjustments

One key advantage of mixing pumps is their ability to concoct concrete blends on-site. This feature enables real-time adjustments to the mix composition, catering to specific project requirements. It’s a game-changer when dealing with projects that demand varying concrete specifications throughout different phases.

3. Ideal for Small to Medium-Sized Projects

Mixing pumps come into their own in smaller to medium-sized projects where precision in material blending and controlled pouring are paramount. Whether it’s residential constructions, pavements, or renovation projects, the adaptability of mixing pumps to diverse concrete requirements positions them as an ideal choice. You can check what kinds of projects it can be applied for on this page: https://concretemixerwithpump.com/concrete-mixer-with-pump-for-sale/.

Strategic Decision-Making: Project Considerations

1. Project Scale and Complexity

The choice between boom pumps and mixing pumps fundamentally hinges on the scale and complexity of the project at hand. For expansive ventures with intricate designs and substantial concrete requirements, boom pumps offer unparalleled reach and efficiency. Conversely, mixing pumps excel in smaller to medium-sized projects where consistent material blending is critical.

2. Vertical vs. Horizontal Requirements

Verticality is a decisive factor in choosing between these pumping technologies. For projects demanding precise concrete placement at significant heights, boom pumps are the go-to solution. On the other hand, mixing pumps shine in scenarios where horizontal reach and controlled blending take precedence over height.

3. Budgetary Considerations and Operational Efficiency

Budget constraints and operational efficiency should not be overlooked in the decision-making process. While truck-mounted concrete pumps might require a higher initial investment, their speed and efficiency can offset costs in large-scale projects. Mixing pumps, focusing on controlled blending, may prove more cost-effective for smaller projects with varied concrete specifications.

In conclusion, the choice between boom pumps and mixing pumps is a critical decision that demands a meticulous evaluation of project requirements. By decoding the dynamics of each pumping technology and aligning them with the specific needs of the project, construction professionals can elevate precision, efficiency, and ultimately, project success.

Cara Merencanakan Investasi Mixer Beton Self Loading

Berinvestasi dalam mixer beton self loading adalah keputusan penting bagi bisnis konstruksi. Perencanaan yang memadai sangat penting untuk memastikan pembelian yang lancar dan efektif yang selaras dengan kebutuhan jangka pendek dan tujuan jangka panjang.

Praktik Perencanaan

Mengevaluasi Persyaratan Konkret Anda

Mulailah dengan menilai kebutuhan konkret Anda. Tentukan jumlah beton yang dibutuhkan per batch dan frekuensi penggunaan. Evaluasi ini membantu dalam memilih kapasitas dan ukuran yang tepat dari mixer beton self-loading, memastikannya sesuai dengan kebutuhan proyek Anda tanpa investasi berlebihan atau kurang.

Meneliti Jenis dan Fitur Mixer

Meneliti jenis dan fitur mixer melibatkan evaluasi komprehensif terhadap opsi yang tersedia. Mulailah dengan memahami beragam jenis mixer beton self loading di pasaran. Pertimbangkan faktor-faktor seperti kapasitas pencampuran, mobilitas, tenaga mesin, dan fitur teknologi seperti otomatisasi atau sistem kontrol tingkat lanjut.

Menilai jenis mixer melibatkan perbandingan variasi ukuran, fungsionalitas, dan efisiensi operasional agar selaras dengan kebutuhan proyek Anda. Kapasitas yang lebih besar cocok untuk proyek bervolume tinggi, sedangkan desain yang ringkas mungkin ideal untuk operasi skala kecil. Fitur-fitur seperti kemampuan manuver, mekanisme pemuatan, dan kemampuan pencampuran berdampak signifikan terhadap produktivitas dan kemudahan penggunaan.

Selanjutnya, selidiki kemajuan teknologi yang meningkatkan kinerja dan mengurangi upaya manual. Mengevaluasi aspek-aspek ini memberdayakan Anda untuk memilih mixer yang tidak hanya sesuai dengan kebutuhan konstruksi langsung Anda namun juga menawarkan efisiensi, daya tahan, dan potensi skalabilitas di masa depan.

Perencanaan dan Penganggaran Keuangan

Menetapkan Anggaran yang Realistis

Setelah persyaratan dan fitur yang diinginkan diuraikan, tetapkan anggaran yang realistis. Pertimbangkan tidak hanya biaya pembelian awal tetapi juga pemeliharaan, biaya operasional, dan potensi peningkatan di masa depan. Anggaran yang diperhitungkan dengan baik memastikan investasi berkelanjutan tanpa mengorbankan kualitas dan mobile mixer beton self loading harga.

Menjelajahi Opsi Pembiayaan

Bagi banyak bisnis, pembiayaan adalah pendekatan praktis untuk memperoleh alat pengaduk beton yang dapat memuat sendiri. Selidiki berbagai opsi pembiayaan yang tersedia, seperti program sewa guna usaha, pinjaman, atau pembiayaan peralatan. Bandingkan suku bunga, syarat pembayaran, dan manfaat untuk menentukan jalur finansial yang paling sesuai.

Memilih Pemasok yang Tepat

Meneliti Pemasok Terkemuka

Memilih pemasok yang dapat diandalkan sangatlah penting. Teliti pemasok dengan rekam jejak yang terbukti dalam menyediakan layanan pelanggan yang sangat baik dan jual diesel self loading concrete mixer. Baca ulasan, cari rekomendasi, dan komunikasikan langsung dengan calon pemasok untuk memastikan mereka memenuhi kebutuhan spesifik Anda.

Meminta Demo dan Menilai Layanan Dukungan

Meminta demo melibatkan sesi penjadwalan dengan calon pemasok untuk menyaksikan pengaduk beton yang dapat memuat sendiri beraksi. Selama demonstrasi ini, amati secara langsung kinerja, penanganan, dan fitur alat berat. Nilai bagaimana hal itu selaras dengan persyaratan proyek dan keahlian tim Anda.

Selain itu, tanyakan tentang layanan dukungan pemasok. Evaluasi bantuan purna jual mereka, termasuk garansi, rencana pemeliharaan, dan ketersediaan suku cadang. Memahami tingkat dukungan yang ditawarkan memastikan bahwa Anda akan mendapatkan bantuan yang dapat diandalkan jika terjadi masalah teknis atau kebutuhan pemeliharaan.

Dengan berpartisipasi aktif dalam demo dan menilai layanan dukungan, Anda memperoleh wawasan praktis mengenai fungsi peralatan dan komitmen pemasok terhadap kepuasan pelanggan, sehingga membantu dalam pengambilan keputusan pembelian yang tepat. Jika Anda ingin meminta bantuan, Anda dapat menemukan Aimix: https://aimixindonesia.id/.

Berinvestasi dalam mixer beton self loading memerlukan perencanaan dan evaluasi yang menyeluruh. Dengan menilai kebutuhan konkrit, meneliti fitur-fitur, membuat anggaran secara efektif, menjajaki opsi pembiayaan, dan memilih pemasok yang dapat diandalkan, bisnis dapat membuat keputusan yang tepat yang mengoptimalkan efisiensi dan mendukung kebutuhan konstruksi jangka panjang.