Affordable Steel Warehouse Structures for Sale: Maximizing Your Budget

In today’s fast-paced business environment, having an efficient and reliable storage solution is essential for companies across various industries. Steel warehouse structures offer durability, flexibility, and cost-effectiveness, making them an attractive option for businesses looking to maximize their budgets. This article explores the benefits of affordable steel warehouse structure for sale, how to find the best deals, and tips for making the most of your investment.

Why Choose Steel Warehouse Structures?

Steel warehouse structures have gained popularity due to their numerous advantages over traditional building materials. Here are some key benefits:

- Durability: Steel is inherently strong and resistant to environmental factors such as mold, pests, and extreme weather conditions. This longevity ensures that your investment remains sound over time, reducing maintenance and replacement costs.

- Cost-Effectiveness: Steel structures typically have lower construction and maintenance costs compared to wood or concrete buildings. Their prefabricated components can be assembled quickly, minimizing labor costs and reducing the overall time to completion.

- Flexibility: Steel warehouses can be designed to accommodate various layouts and sizes, making them adaptable to different business needs. Whether you require open floor space for storage or specific sections for office space, steel structures can be customized to fit your requirements.

- Energy Efficiency: Modern steel warehouse designs often incorporate insulation and energy-efficient systems, leading to lower energy bills and a smaller environmental footprint. This not only helps the planet but also contributes to long-term savings.

Finding Affordable Steel Warehouse Structures for Sale

To maximize your budget while purchasing a steel warehouse structure, consider the following strategies:

- Research Suppliers: Start by researching reputable suppliers that specialize in steel warehouse structures. Look for companies with positive reviews, a solid track record, and transparent pricing. Request quotes from multiple suppliers to compare costs and options.

- Explore Used or Refurbished Structures: Purchasing used or refurbished steel warehouses can significantly reduce your investment costs. These structures are often available at a fraction of the price of new ones and can still provide the durability and functionality you need. Ensure that any used structures come with proper documentation regarding their condition and history.

- Consider Modular or Prefabricated Options: Modular or prefabricated steel warehouses are designed for quick assembly, reducing construction time and labor costs. These structures often come with pre-engineered designs that meet building codes, making them a cost-effective solution for businesses on a budget.

- Look for Promotions and Discounts: Many suppliers offer seasonal promotions, discounts for bulk purchases, or financing options. Keep an eye out for these opportunities, as they can significantly lower your overall costs.

Maximizing Your Budget: Tips for Cost-Effective Solutions

Once you’ve found affordable steel warehouse structures for sale, consider the following tips to maximize your budget further:

- Plan for Future Growth: When selecting a steel warehouse structure, consider your long-term needs. Choosing a larger or expandable design can save you money in the future, as you won’t need to invest in additional structures as your business grows.

- Invest in Quality: While it may be tempting to opt for the lowest-priced option, investing in high-quality materials and workmanship will pay off in the long run. Quality structures will require less maintenance and offer better performance over time.

- Evaluate Financing Options: Many suppliers offer financing plans to help spread the cost of your investment over time. Explore these options to find a payment plan that aligns with your budget and cash flow.

- Factor in Additional Costs: When budgeting for your steel warehouse structure, don’t forget to account for additional costs such as site preparation, permits, and utility connections. Having a comprehensive budget will help you avoid unexpected expenses. Aicrane has been in steel structure business for many years, offering reliable steel structure solutions to suit different requirements, and you can contact the company to get more details and steel structure price.

Consider Location and Accessibility

The location of your steel warehouse can significantly impact overall costs, including transportation, site preparation, and accessibility. Choosing a site with easy access to major transportation routes can minimize logistics costs and improve efficiency.

Additionally, ensure that the site is properly zoned for your intended use, as zoning regulations can affect construction timelines and costs. Collaborating with local authorities can help streamline the permitting process and avoid potential delays.

Conclusion

Investing in an affordable steel warehouse structure is a smart move for businesses looking to maximize their budgets while ensuring reliable storage solutions. With their durability, flexibility, and cost-effectiveness, steel warehouses are a practical choice for various industries.

By conducting thorough research, exploring used options, and maximizing your budget with strategic planning, you can find the ideal steel warehouse structure that meets your needs without breaking the bank. In a competitive market, a well-chosen steel warehouse can enhance your operational efficiency, enabling your business to thrive for years to come.

How a 100 Ton Bridge Crane Boosts Productivity in Heavy Lifting Projects

In industries where heavy lifting is a constant challenge—such as construction, manufacturing, shipping, and metalworking—efficiency and productivity are paramount. The right equipment can drastically improve workflow, reduce downtime, and ensure safety on the job site. One of the most valuable tools for heavy lifting operations is the 100 ton bridge crane. With its impressive lifting capacity, adaptability, and operational efficiency, the 100 ton bridge crane has become an essential asset for large-scale projects.

This article explores how a 100 ton bridge crane enhances productivity in heavy lifting tasks and the key benefits it brings to industries handling massive loads.

Efficient Handling of Massive Loads

One of the most obvious advantages of a 100 ton bridge crane is its capacity to lift and move incredibly heavy loads. Whether it’s large steel beams, bulky machinery, or industrial components, the crane’s powerful lifting capability eliminates the need for multiple smaller cranes or lifting systems. This translates to fewer lifts, shorter work cycles, and less time spent on each task.

By reducing the number of lifts required for handling heavy materials, a 100 ton bridge crane minimizes the time and effort needed to complete complex lifting jobs. This results in faster project timelines, allowing businesses to meet tight deadlines and handle a larger volume of work.

Increased Operational Flexibility

The 100 ton bridge crane’s versatility is another major factor that boosts productivity. Unlike fixed cranes or limited-capacity lifting systems, bridge cranes are mounted on tracks that allow them to move horizontally along the length of a building or work area. This mobility enables operators to access various parts of the facility without the need for additional cranes or equipment.

Moreover, a 100 ton bridge crane can be customized with different lifting mechanisms, including hoists, grabs, and magnets, depending on the material being handled. This adaptability makes it easier to switch between different lifting tasks without extensive reconfiguration, further increasing operational efficiency.

Reducing Downtime Through Advanced Automation

Modern 100 ton bridge cranes often come equipped with advanced automation features, which are critical for improving operational speed and precision. Automated systems can control lifting, positioning, and movement, ensuring that each load is handled accurately and efficiently. With programmable controls, operators can set specific lifting parameters, reducing human error and the time spent adjusting loads manually.

Additionally, automated systems can reduce downtime associated with maintenance or repairs by monitoring the crane’s performance in real-time. Predictive maintenance features help detect potential issues before they lead to costly breakdowns, ensuring that the crane remains operational with minimal interruptions.

Improved Safety for Workers and Equipment

Safety is a top priority in heavy lifting operations, and a 100 ton heavy duty crane contributes to a safer working environment by minimizing risks associated with manual lifting and handling. The crane’s robust structure and precise controls allow operators to lift and move loads with confidence, reducing the likelihood of accidents or equipment damage.

Furthermore, many 100 ton bridge cranes are designed with built-in safety features such as load limiters, emergency stop buttons, and anti-sway technologies. These features ensure that loads are moved steadily and securely, preventing sudden swings or drops that could lead to injuries or material damage.

A safer work environment means fewer accidents, less downtime, and more consistent project progression. This focus on safety enhances overall productivity, as workers can operate with the assurance that the equipment they are using is designed to handle even the most challenging lifting tasks safely.

Cost Savings Through Efficient Resource Utilization

Incorporating a 100 ton bridge crane into heavy lifting projects can also lead to significant cost savings. The crane’s high load capacity means that fewer lifts are required to complete a task, reducing labor costs and the amount of time spent on each project. Additionally, the crane’s ability to handle diverse materials and tasks eliminates the need for multiple lifting systems, further reducing equipment and operational costs.

Moreover, by reducing the risk of accidents and equipment damage, a 100 ton bridge crane helps companies avoid costly repairs and liability expenses. In industries where downtime or delays can result in significant financial losses, the crane’s ability to improve efficiency and minimize risks makes it a cost-effective solution for long-term heavy lifting operations. To get a reliable crane solution of cost savings, you are advised to choose and cooperate with Aicrane supplier for an ideal one. Just contact the company team at anytime you want.

Optimized Workflow and Project Management

A 100 ton bridge crane allows companies to optimize their workflow by streamlining material handling processes. With the ability to quickly and efficiently lift, move, and place heavy materials, the crane enhances coordination between different stages of a project. For example, in a manufacturing facility, a bridge crane can easily transport raw materials from storage areas to production lines and move finished products to shipping zones without disrupting other activities.

This improved material flow helps prevent bottlenecks and ensures that tasks are completed in a logical sequence. As a result, project managers can maintain better control over timelines and resource allocation, leading to more efficient and profitable operations.

Enhancing Competitive Edge

For companies involved in heavy lifting projects, investing in a 100 ton bridge crane can significantly enhance their competitive edge. By improving productivity, reducing costs, and increasing operational safety, the crane enables businesses to take on larger and more complex projects that require heavy lifting. Companies equipped with the right tools are better positioned to secure contracts and meet client expectations, leading to sustained growth in the industry.

A 100 ton bridge crane is more than just a powerful piece of equipment—it’s a productivity-boosting solution for heavy lifting projects across various industries. From its ability to efficiently handle massive loads and increase operational flexibility to its safety features and cost-saving potential, the 100 ton bridge crane helps businesses optimize their workflow, meet project deadlines, and improve overall profitability.

For companies looking to enhance their heavy lifting capabilities, investing in a 100 ton bridge crane is a strategic decision that can deliver long-term benefits in terms of efficiency, safety, and project management.

How to Keep Your Self-Loading Mixer Performing at Its Best

Self-loading mixers are essential tools in the construction industry. They combine loading, mixing, and discharging functions into one machine. To ensure they perform at their best, regular maintenance and proper operation are crucial. This guide will help you maximize the efficiency and lifespan of your self-loading concrete mixer machine.

Regular Maintenance for Optimal Performance

Regular maintenance is key to keeping your self-loading mixer in top condition. A consistent maintenance schedule can prevent breakdowns and ensure smooth operation.

Daily Inspections

Conduct daily inspections to check for any visible wear and tear. Look for leaks, cracks, or loose components. Addressing minor issues promptly can prevent major problems later.

Lubrication

Lubricate all moving parts regularly. Proper lubrication reduces friction and wear, ensuring smooth operation. Follow the manufacturer’s guidelines for the type and frequency of lubrication.

Cleaning

Clean the mixer after each use. Concrete buildup can affect the machine’s performance and lead to malfunctions. Use a pressure washer to clean the drum, hopper, and other components thoroughly.

Proper Operation Techniques

Understanding and following proper operation techniques can significantly impact the performance and lifespan of your self-loading mixer truck. Here are some key points to consider:

Loading

Ensure the materials are loaded correctly into the hopper. Overloading can strain the machine and affect the quality of the mix. Use the recommended proportions of cement, sand, and aggregates.

Mixing

Monitor the mixing process closely. The drum should rotate at the recommended speed for optimal mixing. Avoid running the mixer at high speeds for prolonged periods, as this can cause excessive wear.

Discharging

Discharge the concrete promptly after mixing. Delays can cause the mix to set inside the drum, making it difficult to clean. Use the discharge chute or other mechanisms as recommended by the manufacturer.

Addressing Common Issues

Even with regular maintenance and proper operation, issues can still arise. Knowing how to address common problems can help you keep your self-loading mixer performing at its best.

Clogged Hopper

A clogged hopper can affect the loading process. Check for any obstructions and remove them promptly. Regular cleaning can prevent this issue.

Inconsistent Mixture

An inconsistent mixture can compromise the quality of your concrete. Ensure the drum rotates at the proper speed and that the materials are loaded in the correct proportions.

Hydraulic System Issues

Hydraulic system issues can affect the mixer’s operation. Regularly check the hydraulic fluid levels and look for any leaks. Addressing these issues promptly can prevent more serious problems.

Tips for Extending the Lifespan of Your Self-Loading Mixer

Extending the lifespan of your self-loading mixer involves more than just regular maintenance. Following these additional tips can help you get the most out of your machine.

Choosing the Reliable Manufacturer

As a concrete equipment manufacturer, AIMIX Group is known for producing efficient and reliable equipment. Know more about it by clicking this link: https://aimixgroup.com/.

Training Operators

Ensure that all operators are well-trained. Proper training can prevent operational errors that can lead to damage. Experienced operators can also identify potential issues before they become serious problems.

Using Quality Materials

Use high-quality materials for your concrete mix. Poor-quality materials can cause excessive wear on the mixer. They can also affect the consistency and strength of the concrete.

Storing Properly

Store the mixer in a dry, sheltered area when not in use. Exposure to harsh weather conditions can cause rust and other damage. Proper storage can significantly extend the lifespan of your machine.

Conclusion

Keeping your self-loading mixer performing at its best requires regular maintenance, proper operation, and addressing common issues promptly. Daily inspections, lubrication, and cleaning are essential for optimal performance. Proper loading, mixing, and discharging techniques can prevent operational errors. Address issues like clogged hoppers, inconsistent mixtures, and hydraulic problems as soon as they arise. Finally, train operators, use quality materials, and store the mixer properly to extend its lifespan.

How to Find Reliable Self Loading Concrete Mixer Manufacturer in Ghana, like AIMIX?

In the burgeoning construction industry of Ghana, the demand for efficient machinery has never been higher. Among the myriad of equipment available, self-loading concrete mixers stand out due to their versatility and efficiency.

However, the crux of the matter lies in sourcing reliable manufacturers who can provide high-quality machinery. This article delves into the essential strategies and criteria for identifying trustworthy self loading concrete mixer manufacturers in Ghana, such as AIMIX, while highlighting the significance of due diligence in this critical investment.

Understanding the Landscape of Concrete Mixer Manufacturers

The construction sector is replete with manufacturers, each vying for attention. However, not all manufacturers offer the same level of quality and reliability. It is imperative to comprehend the dynamics of the local market, particularly the factors that distinguish reputable manufacturers from the less scrupulous ones. By examining industry trends, customer reviews, and the overall reputation of manufacturers, potential buyers can make informed decisions that will significantly impact their projects.

Assessing Manufacturer Credibility

One of the foremost steps in finding a reliable self-loading concrete mixer manufacturer is assessing their credibility. Credibility can be gauged through various metrics, including years of operation, certifications, and industry affiliations. Manufacturers that have stood the test of time often possess a wealth of experience that translates into superior product quality.

Evaluating Experience and Reputation

Experience is not merely a number; it reflects a manufacturer’s ability to adapt to changing technology and market demands. A manufacturer like AIMIX, with a proven track record, exemplifies reliability. Additionally, examining customer testimonials provides insight into the manufacturer’s reputation. A plethora of positive reviews often indicates consistent quality and customer satisfaction.

Certifications and Compliance

Certifications serve as a testament to a manufacturer’s adherence to industry standards. Look for manufacturers certified by recognized organizations, as this underscores their commitment to quality and safety. Compliance with local regulations and international standards is non-negotiable for any manufacturer aspiring to be deemed reliable.

Analyzing Product Quality and After-Sales Support

Product quality is paramount when selecting a self-loading concrete mixer. A thorough examination of the materials used and the manufacturing process can provide insights into the durability and functionality of the machinery. Furthermore, after-sales support is an often-overlooked aspect that can significantly affect the long-term satisfaction of the buyer.

Inspecting Manufacturing Processes

Investigating the manufacturing processes employed by potential manufacturers can yield invaluable information. Manufacturers that utilize advanced technologies and adhere to stringent quality control measures are more likely to produce reliable equipment. Inquire about the sourcing of materials and whether they engage in rigorous testing protocols.

Evaluating After-Sales Service

After-sales service is a critical component of the overall value proposition. A reliable manufacturer should offer comprehensive support, including installation, maintenance, and readily available spare parts. The presence of a responsive customer service team can significantly mitigate downtime and ensure that your investment remains operational.

Utilizing Technology for Research and Comparison

In the digital age, technology plays a pivotal role in research. Utilizing online resources can streamline the process of finding a reliable manufacturer of self loading concrete mixer for sale in Ghana. Websites, forums, and social media can serve as platforms for gathering information and comparing different manufacturers.

Leveraging Online Reviews and Testimonials

Online reviews are a treasure trove of information. By exploring platforms where customers share their experiences, potential buyers can gain insights into the strengths and weaknesses of various manufacturers. Pay particular attention to recurring themes in reviews, as they often highlight critical aspects of product performance and customer service.

Engaging in Industry Forums

Participating in industry-specific forums can facilitate direct communication with other construction professionals. These interactions can provide firsthand recommendations and warnings about specific manufacturers based on real-world experiences. Engaging with peers offers a unique perspective that can enhance your decision-making process.

Comparative Analysis of Manufacturers

A comprehensive comparative analysis of multiple manufacturers can illuminate the most suitable options. By creating a matrix that evaluates each manufacturer based on key criteria—such as self loading mixer product quality, price, after-sales service, and customer feedback—buyers can make an informed choice that aligns with their project needs and budget.

Conclusion: The Imperative of Diligence in Selection

Finding a reliable self-loading concrete mixer manufacturer in Ghana, such as AIMIX, is not merely a matter of convenience; it is an imperative for ensuring the success of construction projects. By understanding the landscape of manufacturers, assessing credibility, analyzing product quality, and utilizing technology for research, stakeholders can make informed choices. The investment in thorough research and due diligence pays dividends in the form of enhanced operational efficiency and reduced risk. As the construction industry in Ghana continues to evolve, staying informed and vigilant in the selection process will remain paramount.

Can the Asphalt Plant for Sale Adapt to Varying Climate Conditions Along Different Stretches of Highway?

When it comes to the intricate dance of road construction and maintenance, one of the pivotal players in the orchestra of asphalt production is the asphalt plant. For engineering industries and the road and bridge construction sector, choosing the right asphalt plant can be a make-or-break decision. AIMIX, a leading manufacturer of asphalt mixing plants, stands out in this arena with its versatile offerings.

Understanding the Needs Across Diverse Climates

Highways are not static entities; they traverse diverse landscapes and climates, from the scorching heat of desert highways to the icy chill of mountain passes. An asphalt plant must be more than just a machine—it needs to be a reliable partner that adapts to these varying conditions seamlessly.

AIMIX’s asphalt plants are engineered with this diversity in mind. Whether it’s an asphalt mixer plant or an asphalt batch plant, AIMIX integrates cutting-edge technology to ensure robust performance across different environmental challenges. The materials used in AIMIX asphalt mixing plants for sale are carefully selected to withstand temperature variations and maintain optimal efficiency.

Efficiency and Adaptability at the Forefront

Efficiency is not just about speed; it’s about consistent performance under all conditions. AIMIX asphalt plants excel in efficiency, minimizing downtime and maximizing output. This reliability is crucial for meeting project deadlines and maintaining cost-effectiveness.

Moreover, AIMIX understands that adaptability is key. Their asphalt mixer plants are designed to handle different types of aggregates and asphalt mixes, allowing contractors the flexibility to adjust formulations based on project-specific requirements.

Advanced Technology Driving Innovation

What sets AIMIX apart is their commitment to innovation. Their asphalt plant sale can incorporate advanced control systems that optimize the mixing process, ensuring homogeneity and quality in every batch. This precision is essential for producing durable asphalt mixes that meet industry standards.

Furthermore, AIMIX’s dedication to sustainability is evident in their asphalt manufacturing plants. By implementing eco-friendly practices and technologies, AIMIX reduces environmental impact without compromising on performance.

Customer-Centric Approach

Choosing an asphalt plant is a significant investment, and AIMIX understands the importance of customer satisfaction. Their after-sales support is comprehensive, providing maintenance services and technical assistance to ensure uninterrupted operation of their plants.

For engineering industries and contractors in the road and bridge construction sector, reliability and performance are non-negotiable. AIMIX’s reputation as a trustworthy manufacturer of asphalt batch plants for sale is backed by testimonials from satisfied customers worldwide.

The Verdict: Why AIMIX?

In conclusion, when considering an asphalt plant for sale, AIMIX emerges as a top contender. Their asphalt mixer plants and asphalt batch plants are engineered to not only meet but exceed industry standards. From adaptability across climates to technological innovation and customer support, AIMIX Group delivers a comprehensive package that addresses the diverse needs of road and bridge construction.

For those navigating the complex terrain of highway construction, AIMIX stands as a reliable partner, ensuring smooth operations and superior outcomes. Explore AIMIX’s range of asphalt plants today and witness firsthand why they are the preferred choice for leading engineering industries worldwide.

Invest in excellence. Choose AIMIX.

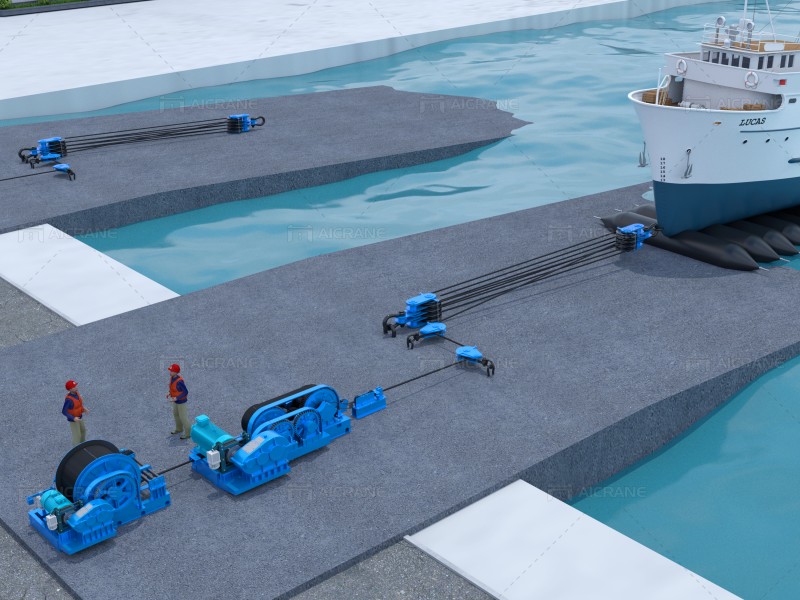

Boat Slipway Winches for Commercial Use: Meeting Industry Standards

Boat slipway winches are indispensable in the marine industry, playing a crucial role in the launch and retrieval of vessels from slipways. These powerful devices are designed to handle the demanding tasks associated with commercial boating operations, ensuring safety, efficiency, and reliability. In this article, we will delve into the importance of boat slipway winches for commercial use, the various types available, industry standards they must meet, and the benefits they offer.

Importance of Boat Slipway Winches in Commercial Use

Commercial boating operations, such as shipbuilding, repairs, and maintenance, require the frequent and safe handling of vessels. Boat slipway winches facilitate the smooth transfer of boats between land and water, making them essential for:

Efficiency: Winches streamline the process of launching and retrieving vessels, significantly reducing the time and labor required compared to manual methods. This efficiency is crucial in commercial settings where time is money.

Safety: Handling heavy vessels manually poses significant risks to personnel and equipment. Slipway winches are designed to bear heavy loads, ensuring safe and controlled movements, which minimizes the risk of accidents and damage.

Precision: These winches offer precise control over the movement of vessels, allowing for accurate positioning and handling. This precision is vital during maintenance, repairs, and inspections.

Types of Boat Slipway Winches

Boat slipway winches come in various types, each designed to meet specific operational needs. The most common types include:

Electric Winches: Electric winches are powered by electricity and are known for their ease of use and efficiency. They are suitable for a range of commercial applications, providing consistent performance and requiring less manual effort.

Hydraulic Winches: Hydraulic winch machines are powered by hydraulic systems and are favored for their immense pulling power and durability. They are ideal for handling larger vessels and heavy-duty operations.

Manual Winches: While less common in commercial settings due to their limited capacity, manual winches can still be useful for smaller vessels or backup purposes. They are powered by human effort and are typically more cost-effective.

Air Winches: Also known as pneumatic winches, these are powered by compressed air. They are often used in environments where electric or hydraulic power sources are impractical or hazardous.

Industry Standards for Boat Slipway Winches

To ensure the safety and reliability of boat slipway winches, there are several industry standards and regulations that manufacturers and operators must adhere to. Some of the key standards include:

Load Capacity: Winches must be rated for the maximum load they are expected to handle. This rating ensures that the winch can safely bear the weight of the vessel and any additional equipment. There are light duty and heavy duty winches to suit different needs.

Material and Construction: Winches must be constructed from durable materials that can withstand the harsh marine environment. Corrosion-resistant materials, such as stainless steel, are commonly used to ensure longevity.

Safety Features: Modern winches are equipped with safety features such as emergency stop mechanisms, overload protection, and fail-safe brakes. These features are essential for preventing accidents and ensuring safe operation.

Compliance with Regulations: Winches must comply with local and international marine safety regulations, such as those set by organizations like the International Maritime Organization (IMO) and the American Bureau of Shipping (ABS).

Benefits of Using High-Quality Boat Slipway Winches

Investing in high-quality boat slipway winches offers several benefits for commercial operations:

Enhanced Productivity: High-quality winches enable faster and more efficient handling of vessels, which can significantly boost productivity in shipyards and maintenance facilities.

Reduced Downtime: Reliable winches minimize the risk of equipment failure, reducing downtime and ensuring that operations run smoothly and without interruptions.

Cost Savings: While high-quality winches may come with a higher upfront cost, their durability and efficiency lead to long-term cost savings by reducing the need for repairs and replacements.

Improved Safety: Advanced safety features and robust construction ensure that operations are carried out safely, protecting both personnel and equipment.

Versatility: Modern slipway winches are designed to handle a wide range of vessels and operational scenarios, making them versatile tools for any commercial marine setting.

Boat slipway winches are critical components in the commercial marine industry, providing the power and control needed to safely and efficiently handle vessels. By meeting industry standards and offering numerous benefits, these winches play a vital role in enhancing productivity, safety, and overall operational efficiency. When selecting a boat slipway winch for commercial use, it is essential to consider factors such as load capacity, construction quality, safety features, and compliance with regulations. Investing in a high-quality winch is a smart decision that can lead to significant long-term advantages for any marine operation. For more information about winch types, uses, features and advantages, you can check this website now https://aicranemachine.com/.

Essential Upgrades for Your Jaw Crusher Machine

In the world of construction and mining, the jaw crusher plays a vital role in breaking down large materials into smaller, manageable pieces. Whether you’re crushing gravel, operating a small stone crusher for local projects, or managing an industrial-scale operation, ensuring your jaw crusher is running at optimal efficiency is crucial. Over time, wear and tear can diminish the performance of your machine. Upgrading certain components can significantly enhance functionality, extend the lifespan of your equipment, and increase operational efficiency. This article explores essential upgrades that can breathe new life into your jaw crusher.

Enhancing Durability with Wear Parts

Upgrading Jaw Plates

The jaw plates are among the most critical wear parts of a jaw crusher(trituradora de mandibula para piedra). These are the main surfaces that apply force to crush the material. Over time, they wear out, reducing the crusher’s efficiency and productivity. Upgrading to high-quality, abrasion-resistant jaw plates can significantly extend their lifespan. Materials like manganese steel can offer durability and are ideal for crushing harder materials.

Reinforcing Structural Components

The structure of the jaw crusher must withstand immense pressure. Strengthening components such as the frame, hinge points, and bearings can prevent structural failures that lead to downtime. Consider materials that offer high strength-to-weight ratios and are resistant to wear and fatigue.

Improving Efficiency with Technology

Incorporating Automation

Modernizing your jaw crusher with automation technology can significantly boost its efficiency. Automation can ensure the crusher(grava trituradora) operates at the optimal setting for the current task, adjusting settings in real-time for consistent product size and throughput. Furthermore, it can help identify potential issues before they lead to significant damage or downtime, thereby preserving your investment.

Enhancing Safety Features

Safety should always be a top priority in any operation. Upgrading your jaw crusher with advanced safety features can protect your workforce and reduce the risk of accidents. Emergency stop buttons, hydraulic adjustment systems, and overload protection devices are critical upgrades that can make a big difference in daily operations.

Optimizing Performance with Maintenance Tools

Implementing Predictive Maintenance

The integration of predictive maintenance tools, such as vibration analysis and thermal imaging, can preemptively identify when parts are likely to fail or need maintenance. By monitoring the condition of your crusher’s components, you can schedule maintenance and replacements at convenient times, minimizing unplanned downtime. By the way, AIMIX’s crushing equipment(equipos de trituración de AIMIX) has such characteristics, equipped with IoT functions, you can remotely monitor the operation of your equipment.

Regular Calibration and Alignment

Regular calibration and alignment of your jaw crusher are essential to ensure it operates efficiently. Over time, vibrations and wear can misalign critical components, reducing performance and increasing wear on other parts. Investing in tools and training for precise calibration and alignment can pay dividends in prolonged equipment lifespan and reduced operational costs.

Conclusion

A jaw crusher is a formidable piece of equipment, but like all machinery, it requires regular maintenance and occasional upgrades to maintain peak performance. By focusing on enhancing durability with wear parts, improving efficiency with technology, and optimizing performance with maintenance tools, operators can ensure their jaw crusher continues to be a reliable workhorse in their operations. Whether dealing with gravel, a small stone crusher, or a larger industrial model, these upgrades can lead to increased productivity, reduced downtime, and ultimately, a healthier bottom line for your business.

Read More Here: https://aimixtrituradora.com/trituradoras-de-piedra-pequenas/

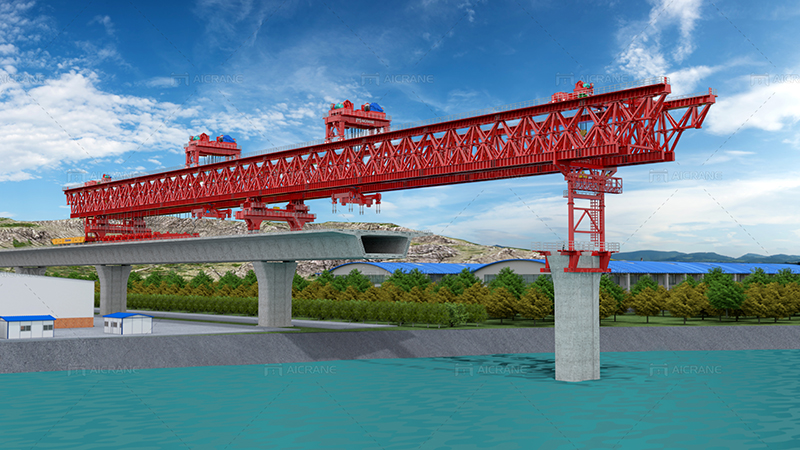

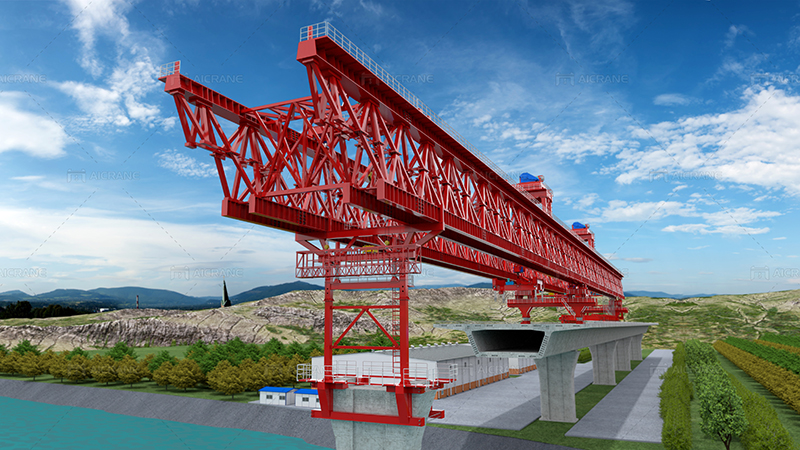

How Does a Bridge Girder Launching Gantry Crane Work?

In the world of civil engineering, the construction of bridges is a complex and awe-inspiring feat that requires precision, innovation, and advanced machinery. Among the many specialized tools used in bridge construction, the Bridge Girder Launching Gantry Crane stands out as a key player. This remarkable piece of engineering equipment plays a crucial role in efficiently and safely placing bridge girders, contributing to the seamless assembly of these colossal structures. In this article, we will delve into the intricacies of how a Bridge Girder Launching Gantry Crane operates, exploring its design, functions, and significance in modern bridge construction.

Understanding the Basics of Launching Gantry Crane:

Before we unravel the inner workings of a Bridge Girder Launching Gantry Crane, it is essential to grasp the fundamentals of bridge construction. Bridge girders, the horizontal supports of a bridge, come in various shapes and sizes depending on the type of bridge being built. These girders must be carefully positioned and secured to form the skeleton of the bridge before other components, such as the deck and railing, can be added.

This is where the Bridge Girder Launching Gantry Crane steps in. Essentially, it is a specialized crane designed for the precise installation of bridge girders. Unlike traditional cranes, the launching gantry crane operates on a system of tracks or rails, allowing it to move horizontally along the length of the bridge during construction.

Key Components and Design of Launching Gantry:

A typical Bridge Girder Launching Gantry Crane consists of several key components, each playing a crucial role in the overall functionality of the system.

Main Girder: The main girder is the primary structural component of the crane, spanning the width of the bridge. It provides the necessary support for the other components and ensures stability during the girder placement process.

Launching Nose: This is the front part of the crane that extends beyond the main girder. The launching nose is equipped with mechanisms for lifting, lowering, and precisely placing the bridge girders.

Lifting Mechanism: The lifting mechanism is responsible for hoisting the bridge girders from the ground and positioning them accurately in place. This mechanism is often equipped with advanced control systems to ensure precision during the lifting and lowering process.

Horizontal Movement System: Unlike conventional cranes, a Bridge Girder Launching Gantry Crane is designed to move horizontally along the length of the bridge. This is achieved through a sophisticated system of tracks or rails that guide the crane to the desired location.

Operational Process of Launching Gantry Crane:

The operation of a Bridge Girder Launching Gantry Crane can be broken down into several key steps, highlighting the precision and coordination required for successful bridge construction.

Positioning: The crane is initially positioned at one end of the bridge using its horizontal movement system. This allows it to access different sections of the bridge during the construction process.

Girder Loading: The lifting mechanism is engaged to hoist a bridge girder from the ground. Advanced sensors and controls ensure that the girder is securely attached and properly aligned for placement.

Horizontal Movement: The crane moves horizontally along the bridge, carrying the lifted girder to its designated position. This horizontal movement is controlled with precision to align the girder accurately.

Girder Placement: Once in position, the crane’s launching nose delicately lowers the bridge girder into place. This step requires meticulous control to ensure that the girder aligns perfectly with the existing structure.

Repeat Process: The entire process is repeated for each successive girder until the bridge’s skeleton is complete. The bridge construction crane continues to move along the bridge, systematically placing girders with remarkable accuracy.

Significance in Bridge Construction:

The Bridge Girder Launching Gantry Crane plays a pivotal role in modern bridge construction for several reasons:

Efficiency: The use of a launching gantry crane significantly speeds up the construction process by allowing for the rapid and precise placement of bridge girders.

Safety: The advanced control systems and automated features enhance safety by reducing the risk of human error during girder placement.

Adaptability: These cranes can be customized to accommodate various bridge designs and specifications, making them adaptable to a wide range of construction projects.

Cost-effectiveness: While the initial investment in a Bridge Girder Launching Gantry Crane may be substantial, the efficiency and speed it brings to the construction process can result in overall cost savings.

Conclusion:

In the realm of civil engineering, the Bridge Girder Launching Gantry Crane stands as a testament to human ingenuity and innovation. Its ability to lift, move, and precisely place bridge girders has revolutionized the construction of bridges, making the process more efficient, safe, and cost-effective. As technology continues to advance, we can expect further refinements and enhancements in the design and functionality of these remarkable machines, contributing to the creation of even more ambitious and awe-inspiring bridges around the world. For more info, visit https://steelmillcranes.com/

Why Your Next Batching Plant Should Be Eco-Friendly

In today’s world, environmental conservation is not just a moral duty but a crucial requirement. The construction industry, known for its significant environmental impact, is now witnessing a pivotal shift toward sustainability. Central to this transformation is the concrete batching plant, a staple in construction projects. This article delves into how adopting environmentally friendly batching plants can reduce ecological footprints and why customers should be part of this green revolution.

The Urgency to Adopt Eco-Friendly Practices in Concrete Production

Concrete production is resource-intensive and contributes to various forms of pollution. However, innovation and technology offer a pathway to mitigate these environmental harms. Transitioning to eco-friendly concrete batching plants is not merely a trend but an essential step for the future of construction.

The Environmental Impact of Traditional Batching Plants

Traditional concrete batching plants are major sources of CO2 emissions, dust, and noise pollution. They consume vast amounts of water and energy, exacerbating their ecological footprint. Recognizing these impacts is the first step towards embracing sustainable alternatives.

Benefits of Eco-Friendly Concrete Batching Plants

Investing in an environmentally friendly batching plant brings multifaceted advantages. Not only does it contribute to the planet’s well-being, but it also enhances operational efficiency and cost-effectiveness in the long run.

Reduced Carbon Footprint

Eco-friendly batching plants are designed to lower CO2 emissions through energy-efficient operations. By integrating renewable energy sources and optimizing production processes, the environmentally friendly concrete mixing plant makes a substantial difference in reducing the carbon footprint of construction projects.

Less Resource Consumption

Advanced water recycling systems and waste management practices in modern batching plants ensure minimal resource wastage. This responsible use of resources not only protects the environment but also translates to savings for businesses.

Compliance with Environmental Regulations

With stricter environmental regulations coming into play, investing in an eco-friendly batching plant ensures compliance and avoids potential penalties. It positions companies as responsible entities committed to sustainable development.

Choosing the Right Eco-Friendly Concrete Batching Plant

Deciding on the most suitable eco-friendly batching plant requires careful consideration of several factors, including technological features, capacity, and after-sales support. Potential customers should seek out concrete batch plants manufacturers who prioritize sustainability alongside quality and efficiency.

Key Features to Look For

When selecting an environmentally friendly batching plant, look for energy-saving designs, advanced dust control systems, and efficient water recycling features. These elements are indicative of a genuinely eco-conscious manufacturing approach.

The Role of Innovation and Technology

Technology plays a critical role in enhancing the eco-friendliness of batching plants. Cutting-edge solutions like automated control systems and AI-driven efficiency optimizations are paving the way for greener construction practices.

Making the Sustainable Choice: A Call to Action

The move towards environmentally friendly concrete batching plants represents a win-win for both the planet and businesses. It’s a testament to the industry’s ability to innovate and adapt in response to environmental challenges. By choosing the concrete mixture plant, customers not only contribute to a healthier planet but also invest in the long-term sustainability of their operations. Now is the time to embrace this green revolution in concrete production and lead the charge toward a more sustainable future.

Why Customers Should Care

Every choice made in the construction process has environmental implications. Opting for an eco-friendly batching plant is a powerful statement of commitment to sustainability. It reflects a forward-thinking mindset that values efficiency, compliance, and corporate responsibility.

The Competitive Edge

Beyond the environmental benefits, adopting green technologies in concrete production offers a competitive advantage. It enhances a company’s reputation, opens up new business opportunities, and attracts customers who prioritize eco-conscious products and services.

Conclusion: Paving the Way for a Greener Future

The transition to environmentally friendly concrete batching plants is not just a possibility but a necessity. As we forge ahead, the construction industry’s role in environmental stewardship becomes increasingly significant. By making informed choices and investing in eco-friendly solutions, we can significantly reduce the ecological impact of construction activities. Together, let’s build a sustainable future, one eco-friendly batching plant at a time.

The journey towards sustainability is a shared responsibility. Eco-friendly batching plants offer a concrete step towards a greener planet. Click here to learn more about concrete batching plant price list. Let’s embrace this opportunity and lead by example in the pursuit of environmental excellence. The time to act is now.