The Financial Aspects of Buying a Concrete Batch Plant for Sale

When it comes to purchasing a concrete batch plant, it’s important to consider not just the equipment and production capabilities, but also the financial aspect. Investing in a concrete batch plant can bring many benefits to your business, including increased efficiency, productivity, and profitability. However, it’s also important to understand the costs involved and the financing options available to ensure that you’re making a smart investment.

Cost Analysis

The cost of a concrete batch plant for sale can vary greatly depending on several factors, including the size and type of concrete batch plant for sale, the equipment included, and the location. Here are a few key considerations:

1. Initial Investment Costs

This includes the cost of the concrete batch plant itself, as well as installation and setup costs, permits, and any necessary upgrades to your existing facilities. For example, if you need to build a new foundation or make electrical upgrades to accommodate the batch plant, these costs will add to the overall expense. The cost of the concrete batch plant itself can range from several hundred thousand dollars for a small plant to several million for a larger, more advanced plant.

2. Operating Costs

Labor, maintenance, utilities, and other ongoing expenses should also be considered. It’s important to understand the long-term costs of running the batching plant for sale in the Philippines, such as wear and tear on equipment, and the cost of replacing parts as needed. For example, the cost of maintenance and repairs can vary depending on the type and age of the equipment, as well as the frequency of use. It’s important to factor these costs into your budget to ensure that you’re not caught off guard by unexpected expenses down the road.

3. Cost Comparisons

If you’re considering a used or refurbished concrete batch plant, it’s important to weigh the potential cost savings against the potential for unexpected repairs or downtime. A used batch plant may be a more cost-effective option in the short-term, but it may also require more maintenance and repairs than a new plant. On the other hand, a new batch plant will likely be more reliable and efficient, but it may also have a higher upfront cost.

Financing Options

When it comes to financing your concrete batch plant, there are several options to consider:

Traditional Bank Loans

Banks offer loans for equipment and business purchases, which may be a good option if you have a strong credit history and a solid business plan. Bank loans typically have a longer repayment term and lower interest rates, but they may also require collateral, such as your business assets. Learn more info here: https://aimixgroup.ph/portable-concrete-batch-plant-for-sale/.

Equipment Financing

This type of financing allows you to pay for the equipment over time, rather than upfront. Equipment financing is typically easier to obtain than a traditional loan, and it allows you to conserve your working capital for other expenses. However, it may also have higher interest rates and a shorter repayment term.

Leasing Options

Leasing a concrete batch plant can be a good option if you’re not ready to make a large upfront investment. Leasing allows you to use the batch plant for a set period of time, typically 3-5 years, after which you can either purchase the equipment or return it. Leasing can be a flexible option that allows you to scale up or down as your business needs change.

Tax Incentives and Depreciation

When you own a concrete batch plant, you may also be eligible for tax incentives and depreciation benefits. Depreciation allows you to write off the cost of the equipment over a set period of time, reducing your taxable income and lowering your overall tax burden. Additionally, there may be other tax incentives available, such as energy-efficient tax credits or deductions for environmentally-friendly equipment. It’s important to consult with a tax professional to understand the tax implications of owning a small concrete batch plant for sale, and to determine what incentives and deductions you may be eligible for.

Looking For A Concrete Batch Plant For Sale?

Are you shopping for a high quality concrete batch plant for sale? If so, you have come to the right place. Concrete batching plants are expensive and require your due diligence when investing in such a machine. Don’t waste your hard earned money on low quality batch plants when you can choose a high quality product at an affordable price by doing your homework properly. There are several aspects to consider when investing in a concrete batching plant for sale. This article provides information on what you should be looking for when shopping for a concrete batching plant for sale.

The first thing is to do a careful analysis of your own business needs and the market you plan to target. Such an analysis will provide you with the most suitable framework to assess the different factors that you need to take into account when investing your hard earned money in a quality concrete batch plant(planta de premezclado). The capacity of the machine is an important consideration. In fact, the capacity of the unit will depend on the volume of fresh concrete you plan to produce on a daily or weekly basis. Do you own a large construction company? If so, you will need a bigger machine to handle your daily concrete needs. On the other hand, if you operate a medium to small construction project, you can depend on a smaller machine for the job.

The type of concrete you plan to produce is another important factor to consider. In fact, there are different concrete batch plants designed for producing different types of concrete. In case you require high strength concrete, you will need a plant that’s tough enough to deal with the solid ingredients required for high strength concrete. Installing the plant in your location is an important consideration when shopping for a batching plant for sale(plantas de concreto en venta). If your project is based in a remote location without a proper road network to reach the area, you may consider investing in a mobile batch plant because of the ease of transportation of such a plant. Mobile plants are compact and easy to transport & operate compared to stationary plants.

The cost of the batch plant should be within your budget range. The best thing is to set your budget first and then shop for a concrete batch plant to match your budget range. Don’t forget to consider shipping, freight, and long term costs like maintenance when calculating your budget. The most important thing is to invest in a high quality batching plant from a reliable manufacturer or supplier in the industry. With hundreds of concrete batch plant manufacturers on the market, finding a suitable manufacturer or supplier isn’t easy. There are many things to consider when looking for a reliable manufacturer to invest in a concrete batching plant for sale. Reputation, expertise, technology, and customer feedback are important considerations visit site: https://aimixgrupo.com/.

The above article provides important information on what you should be looking for when shopping for a concrete batching plant(plantas de concreto moviles) for sale.

Benefits Associated With Self Loading Mixer Trucks From The Philippines

Many of the top self-loading concrete mixers use by companies today originate from the Philippines. They have perfected be the ability to mass-produce these highly efficient concrete mixer trucks. In many situations, you are able to obtain several of them at one time from reliable manufacturers. Once you are using needs, as opposed to your old concrete mixer trucks, you will see a noticeable difference in your efficiency levels. Here is an overview of the many benefits associated with self-loading concrete mixer trucks from the Philippines.

Why Are These Becoming So Popular?

The popularity stems from the choices that they provide users. In the past, the use of only concrete mixer trucks, limited the user in several ways. Although the drum capacity is typically higher with a standard concrete mixer truck, it is challenging to complete jobs quickly. Transiting back and forth between the source of concrete, and the jobsite itself can take up hours. That’s why using a self-loading concrete mixer would be the best choice. You can bring materials with you, produce concrete on demand, and complete jobs at a rapid pace.

How Long Will It Take To Learn How To Use One?

If you want to obtain one or more of these vehicles, there is a slight learning curve once they arrive. There is a control panel on the exterior of the apparatus that will allow you to control many different factors. This will include adding the materials to the mixer itself. It would be best if you also considered the speed at which it will be next and how it will be delivered. The driver will be trained on how to use this console which will help you create as much concrete as you need. Learn more here: https://aimixgroup.ph/.

Are These More Expensive Than Standard Mixer Trucks?

The cost of a self-loading concrete mixer truck will always be much more expensive than a concrete mixer truck with a standard design. That is because of the technology that is built into these systems. It is also because they can help you save a considerable amount of time. The amount of money that you spend is often dependent upon the manufacturer from which you are able to obtain concrete batch plant for sale. However, these same companies will also offer many units at discount prices. This way, you can easily obtain an affordable concrete mixer truck with self-loading capabilities by researching in advance.

There are so many businesses that can benefit from the use of self-loading concrete mixer trucks. They are versatile, and easy to drive, and the console itself is straightforward. If you are able to replace your existing concrete mixer trucks with self-loading units, you will never want to use the others again. As mentioned before, although the capacity for the standard concrete mixer trucks tends to be higher, it does not replace the efficiency levels that the ones can provide. It is important to get several quotes from various companies that are currently selling them in the Philippines. This will lead you to the most reliable companies, with the best mixer trucks with self-loading technology, built into the truck itself. Eventually, you will understand why many people are now only using self-loading concrete mixer plants.

Types of Asphalt Mixing Plants Available To Invest In

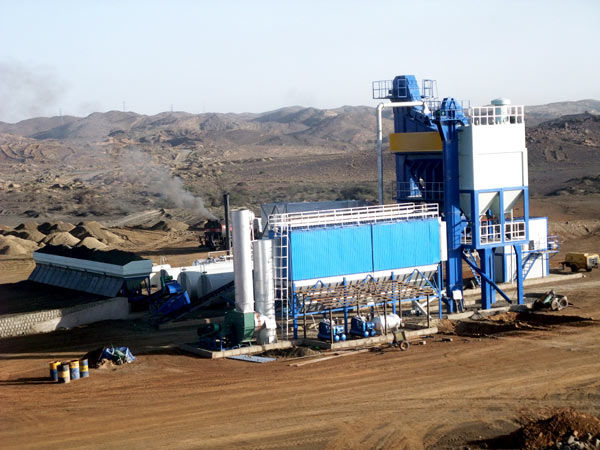

There are two kinds of Asphalt Mixing Plants: batch type and continuous type. Both have different features. Batch type plants stock the aggregates in different compartments and are equipped with a control panel. Continuous type plants screen the aggregates before adding bitumen and filler material. The mixture is then discharged into a truck or a storage silo. The control panel is designed to monitor all the activities of the plant and gives a report on important parameters.

Mobile Asphalt Plants

Mobile asphalt mixing plants are a great option for small and medium scale road construction projects. They are easy to transport and erect, with a low cost of operation. They have advanced features such as high-performance motors, accurate fabricated dryers, and segmented drive sprockets.

These mixing plants are designed to handle a variety of tasks, from small projects to large road construction. They can be used for a variety of applications and are RTO-approved. They provide seamless performance with minimum inputs. They can be used in asphalt plant projects of all types. Their compact designs make them easy to transport and install.

Mobile asphalt mixing plants are the most portable type of asphalt mixing plants, featuring modular construction and transport frame chassis. This allows for easier transport and less space consumption. They can be quickly assembled and disassembled, and their mixing capacity is ten to fifty tons. The mobile units are ideal for highway and city road construction, as well as port construction.

Stationary Asphalt Plants

Stationary asphalt mixing plants are designed for large-scale production of asphalt. They can prepare large amounts of quality asphalt mix in a short period of time, with reduced energy cost. Furthermore, stationary plants tend to have longer service life compared to mobile ones. As such, they are preferred in situations where a high-quality asphalt mix is required on a regular basis.

Stationary asphalt mixing plants are available in various capacities, ranging from 40 to 320 tons per hour. They are generally used in road construction and dam construction. This type of asphalt plant in the Philippines is known for its consistent performance, reliability, and ease of installation.

Drum Mix Plants

A drum mix plant is a powerful asphalt mixing machine. Unlike batch plants, which switch between different mix recipes periodically, drum mix plants produce a consistent asphalt mix in one continuous process. They are typically skid-mounted or portable and range from 120 to 500 tons per hour. Their simple design, high specific mixing capacity, and environmental compliance make them an ideal choice for asphalt producers of all sizes. Here’s a brief explanation of how they work.

A drum mix plant can produce more asphalt per hour than a batch plant. The process involves heating aggregates and homogeneously mixing them with a certain amount of Bitumen and filler. The mixture is then continuously dispensed into a truck or storage silo. Depending on the specifications of the plant, the capacity can range from 20 to 120 tons per hour (TPH). Higher capacities can also be purchased for specific projects.

Continuous Drum Mix Plants

When deciding between continuous drum mix plants for asphalt and batch plants, consider your business’ needs. If your asphalt projects typically require large volumes of material, continuous plants are often a better choice. If your projects involve a high amount of reclaimed asphalt pavement (RAP), a continuous plant will be more efficient.

Continuous drum mix plants for asphalt start by feeding cold aggregates into feeding bins. Typically, a drum mix plant has three or four bin feeders. Aggregates are loaded into different bins according to size and grade, and each bin has movable gates. Aggregates then travel over a long conveyor belt to a scalping screen. In addition to a scalping screen, modern asphalt drum mix plants use a triple heat transfer system to transfer heat from the heating unit to the aggregates. The triple heat transfer system ensures total transfer of heat to the aggregates, using three different heat transfer methods: conductive, connective, and radiation. Learn more information about the asphat plant: https://aimixphilippines.ph/small-portable-asphalt-plants-for-sale/.

Continuous drum mix plants for asphalt are a reliable option. They can be installed in a short time and are designed to handle high volumes of asphalt. Each drum plant contains multiple components, including cold feeder bins, weighing conveyors, and bitumen tanks. They also feature an adjustable burner and control cabins.

Air Pollution Control Devices

Asphalt mixing plants create particulate matter that affects the quality of air in the surrounding area. In order to meet state and local regulations, asphalt plants must install air pollution control devices. These devices can either be new or retrofitted to existing asphalt plants. There are two types of pollution control devices available: a primary dust collection system and a secondary dust collection system. Both systems remove a high percentage of the pollutants created by the asphalt hot mix plant.

In addition to installing these systems, the operator should also consider air pollution control standards. Proper maintenance can make a big difference when it comes to the quality of hot mix asphalt. For instance, dirty burners can release excessive smoke into the atmosphere and cause other combustion by products. The air-to-fuel ratio of a burner is important to achieve the lowest possible air pollution levels.

What Are the Advantages of a Concrete Batching Plant?

What is a Concrete Batching Plant?

A concrete batching plant is construction equipment used to combine various ingredients, such as cement, slag, silica fume, fly ash, aggregate, sand, admixtures, air, and water, to produce concrete. You can, therefore, use concrete batching plants to produce high-quality concrete for construction projects, such as airports, bridges, roads, buildings, and more.

What Are the Advantages of a Concrete Batching Plant?

A concrete batching plant can produce better quality concrete, eliminate storage space on site, reduce construction waste, lower construction costs, reduce congestion on site by reducing the number of workers on site, and save time.

Here are the advantages of a concrete batching plant(planta dosificadora y mezcladora de concreto):

Produce Better Quality Concrete

The main purpose of a concrete batching plant is to produce concrete. The plant uses the correct amounts of ingredients to consistently produce high-quality concrete. Do not hire workers to manually produce concrete. Why? They cannot produce better quality concrete than concrete batching plants.

Eliminate Storage On Site

You will need to store basic materials on the construction site. If there is no extra space on your construction site, you may have a problem storing these materials. Fortunately, you can use your batching concrete plant to store your basic materials. That is why it is perfect for small construction sites.

Different Models to Choose From

There are so many types of concrete batching plants(planta de concreto pequena), including dry concrete batching plants, wet concrete batching plants, stationary concrete batching plants, and mobile concrete batching plants. It is, therefore, easy to find the most suitable concrete batching plant for your construction project.

Reduce Construction Waste

Investing in a mobile concrete batching plant can help reduce construction waste on your construction site. It is easy to move a mobile plant to the construction site. You can use your mobile plant to produce the concrete you need to complete your construction project. You will never produce excess concrete again.

Save Time

It takes time to make concrete manually. In fact, hiring more workers to produce concrete can lead to time wastage. You only need one or two operators to use your concrete batching plant to produce concrete. The plant can produce consistently produce concrete throughout the day.

Reduce Site Congestion

It is not advisable to hire several workers to work on a construction site. If your construction site is congested, accidents can occur. Investing in these plants from AIMIX Group can reduce the number of your workers to reduce site congestion. It is even easy to supervise a few workers. Reduce site congestion to protect your workers from injuries.

Low Maintenance Cost

It is expensive to invest in concrete batching plants. It is, however, cheap to maintain them. Choosing the right manufacturer can lower the cost of maintaining your plant. The manufacturer can maintain your plant at no cost to you. That is why you need to check the after-sale services before choosing your concrete batching plant.

In Conclusion

Investing in a concrete batching plant can reduce your construction costs, protect your workers from injuries, reduce construction waste, save you money, increase your productivity, and help you meet your construction project deadlines. But it is crucial to choose the best concrete batching plant on the market.

Go to website: https://aimixgrupo.com.mx/planta-de-concreto-estacionaria/

Is A Mobile Concrete Batching Plant Worth The Cost?

On-site mixers are ideal for little jobs such as adding new rooms to your home. Larger projects will necessitate the use of a larger concrete mixing plant. This facility is routinely used by major construction and mining businesses. They manufacture massive amounts of cement that can be used immediately on-site. This can also be transported in a vehicle equipped with a spinning drum. These batching plants manufacture ready-to-use cement.

The days of batch plants contributing to global pollution are long gone. Nowadays, you may get a concrete plant with a sustainable design that reduces dust and particle emissions while also reusing wastewater. You also have more options for meeting your cement needs. For consistent cement needs, select a fixed concrete mixing plant. Building construction is an excellent illustration of where this facility is required. Meanwhile, mobile mixing facilities (мобильные бетонные узлы) are ideal for operations that need movement, such as road construction and pipelining.

When looking for a concrete plant, there are a few factors to consider. Keep these in mind while you look for one.

Establish a budget. Do you need to own your own or can you just rent a few? Buying your own is a significant business investment. This tool will be useful to those working in the construction business. Those working on a large one-time project, such as tunneling or pipelining, may decide to lease units instead. Work within your budget and hunt for an apartment within your pricing range.

Consider which batching facility is best for your cement. Take notice of the type of cement you’re utilizing in your construction job. Different types of cement and aggregate (stones, sand, gravel, and pebbles) are handled by different machinery. Determine whether machines can handle the sort of cement you intend to use. The mixing machinery and storage containers for each component are the most important things to look for in any batching plant (бетон завод). Your mixing chamber should be large enough to hold the amount of cement you expect to produce every batch.

Choose the technology you require. Concrete mixing plant units are classified into three types: automatic, semi-automatic, and manual. Automatic self-loading units allow you to enter instructions and they will do the rest. If you feed the machine your cement recipe, it will sort aggregates, correctly measure each ingredient, and load them into the mixer for processing. Manual units allow you to do all of the work, such as sorting, measuring, and feeding the ingredients into the mixer, which subsequently converts the ingredients into cement. To assure quality, most construction businesses utilize automatic and semi-automatic devices. Your cement must comply with local building codes. The mixing procedure has the potential to make or break your cement. Learn more: https://aimixgroup.ru/betonnyy-uzel/.

Mixers come in a variety of sizes, ranging from small portable mixers to large commercial mixing trucks. Choose the appropriate size for your project. Examine the features of each batching plant and ensure that they all work properly. Inspect the mixers, conveyor belts, pipelines, and other mechanical components. Make certain that each piece of equipment has a user-friendly interface that both you and your men will comprehend.

When leasing, inquire whether your provider contains an expert. Most construction sites have a cement mixing expert on staff. If you don’t, or are unfamiliar with the batching plant’s interface, make sure you question your supplier about the products included in your rental package. Will you be able to recruit one of their specialists? Do they only rent out units? Remember these suggestions, and you’ll locate the ideal cement mixing plant. If you want to buy concrete batching plants, AIMIX company is a good choice.

How to Maintain an Industrial Overhead Crane

Industrial overhead cranes are used in many different settings, from factories to construction sites. These cranes help to move heavy loads from one place to another, making them an essential piece of equipment for many businesses. But how do overhead cranes work? Most overhead cranes consist of three main parts: the bridge, the trolley, and the hoist. The bridge supports the trolley, which is used to move the load back and forth. The hoist is mounted on the trolley and is used to lift the load up and down. Together, these three components enable the crane to operate safely and efficiently. But to make sure that everything runs smoothly, you must maintain the crane from time to time. Here’s a maintenance checklist that you can follow:

● It is critical to test the calibration on all indicators of the overhead crane(puente grúa industrial) on a regular basis. This includes load and boom angle indicators. Regular testing helps to prevent potential accidents that could occur if the indicators are not functioning properly.

● Before using an overhead crane, it is important to thoroughly inspect all of the crane’s components to ensure that they are in good working order. This includes checking the motion lever, brakes, and locking devices. The brakes should be examined for any signs of wear or damage, and the motion lever should be tested to ensure that it is working properly.

● The load moment indicator (LMI) or rated capacity indicator (RCI) of the overhead crane provides an indication of the status of the crane with respect to the rated load capacity. The accuracy of this indication must be checked at initial acceptance and periodically thereafter, in accordance with the manufacturer’s instructions. The check shall include, as a minimum, a comparison of the RCI or LMI reading with the actual load on the crane hoist(grua puente) line. If the accuracy check reveals an error greater than 2% of the full-scale reading, the RCI or LMI should be adjusted or replaced in accordance with the manufacturer’s instructions.

● Overhead cranes are used to move heavy loads, and their regular operation is essential for keeping production moving. For this reason, it is important that overhead cranes be inspected on a regular basis. This inspection should include a check for any loose or missing bolts, nuts or pins, as well as any cracked or distorted parts. If any of these issues are found, they should be addressed immediately to avoid potential problems down the road.

● To check the brakes, first, make sure that the power is off and that the crane is in neutral. Then, engage the brake on the bridge by pulling the lever or pressing the button. Next, engage the brake on the trolley motor by turning the handle clockwise. Finally, test the brakes by pulling on the rope or chain. If both brakes are functioning properly, then it is safe to start the overhead crane(puente grua monoviga).

Proper overhead crane maintenance is key to ensuring that your equipment operates safely and efficiently. By following the tips above, you can keep your crane in good condition and avoid costly repairs or replacements.

Read Full Article: https://aicrane.cl

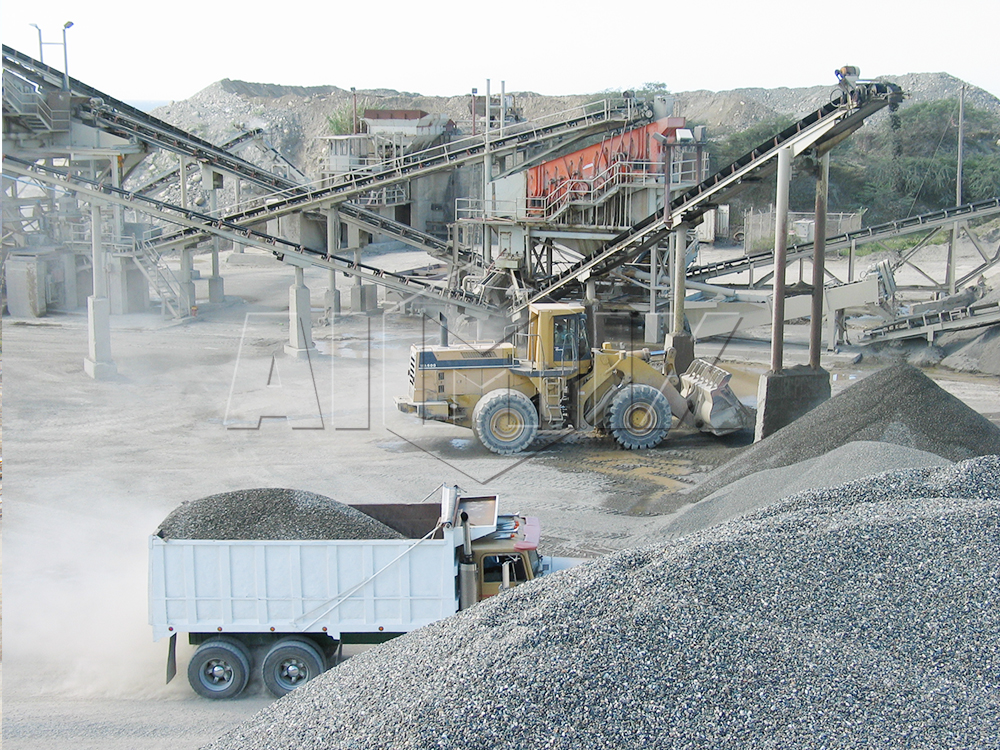

What To Know About The Performance of a Stone Crusher Plant

Performance of a stone crusher plant depends on the configuration of the production units. The use of impact and rolling compression makes the stone crusher plant produce a higher output with low power and noise level. A jaw crusher is a common machine in a stone crushing plant and can work on a variety of stones. The gap setting of this type of crusher determines its output size. A tighter gap setting results in smaller output and a lower throughput capacity.

Configuration of production units affects performance

The configuration of production units in a stone crusher plant(planta trituradora) affects the overall plant performance. This is the result of an optimization process that involves the use of computerized reasoning to simulate the operation of a real plant. The model is used to shape agent degree information for the crushers and improve the final product gradation. Its use is discussed in this article and strategies to optimize the model are sketched.

Impact and rolling compression make the stone crusher plant yield a higher output with a lower noise level and power consumption

The impact and rolling compression crushers work in tandem to produce the highest possible output with minimum noise and power consumption. Both impact and rolling compression produce equal amounts of pressure, resulting in a lower power consumption and noise level. The crushers are made to withstand a variety of abrasive surfaces and are particularly efficient in the crushing of hard rocks.

Symons cone crusher

A Symons cone crusher is a proven choice for high-performance crushing. Its advanced hydraulic system allows it to operate efficiently and reliably, allowing you to focus on other matters that need attention. The cone crusher should be choke-fed for maximum efficiency and productivity, and it must be properly sized for optimal yield. It must also be fed with an appropriate circuitry, including a hopper and feeder. A properly-sized feed system reduces side loading and premature wear.

Gyratory crusher’s cavity profile

This paper presents a numerical model of the Performance of a Gyratory crusher plant, which was developed to simulate the behavior of a crushing plant(plantas de concreto en venta). It uses a combination of a numerical and physical approach to solve the problem. Its results show the impact of operational parameters on the performance of a gyratory crusher. A comparison is made between the base case and the non-uniform filling case. The results of simulations of varying open-side settings, rpm, and Bond’s equation are also presented.

Adequate screening capacity downstream of the crushing circuit

While most producers would want to increase the tons per hour of material that can pass across the screen, there are many ways to increase screening capacity without sacrificing efficiency. Screens are used to separate aggregate material into different sizes. Depending on the size of the stone, the screens may have one or more decks. Screening efficiency is improved by setting the screen’s parameters. A vibrating screen will work at its maximum capacity when it is properly adjusted.

Gyratory crusher’s feed gradation

A Gyratory crusher reduces the size of rocks to a minimum size of about 10 to 15 cm by compressing them. This process reduces the size of rock particles by as much as five to eight times. The size of feed particles is controlled by gyratory’s setting. This type of crusher is typically equipped with hydraulic setting adjustment systems to control the feed gradation and product size. In primary crushers, the gyratory is set to a minimum of 190 rpm. A secondary cone crusher operates at a minimum of 0.75 gyratory setting. Discover here: https://aimixgrupo.com/planta-de-concreto-premezclado-en-venta/

Gyratory crusher’s operating principle

The Gyratory crusher’s operating principle in a stone crusher plant is very similar to that of a jaw or cone-type crusher. In a Gyratory crusher, the crushing head is large, and the area of the discharge opening is directly proportional to the head diameter. The crushing chamber is deep and curved, providing a deep and acute crushing angle while maximizing capacity. The contour at the bottom of the crushing chamber allows for various initial settings. Lower tier concaves are installed to achieve the desired setting and capacity.

AIMIX stone crusher plant

The AIMIX stone crusher plant’s performance is highly dependent on its configuration. Depending on the size of the quarry, rock feed materials, and usage of the final products, different plants can have vastly different layouts. The process of design is usually based on connecting the production unit models. The input and output characteristics are analyzed in detail. The layout of a crushing plant must include the sequence of product demand, the desired product quality and price, and operating costs.

How to Find the Winch For Sale in Kenya

Buying a winch for your truck can be an overwhelming experience. The right one will enhance your truck’s style and functionality, but how do you decide which is the best fit for you? The decision is highly subjective, involving things like bumper color, brushguard style, roller or hawse fairleads, and more. The process is a combination of research, phone calls, and shopping around. Remember, winches are expensive, and freight adds to the cost of purchasing a winch for sale in Kenya. It’s a difficult process, and it takes time.

Home Depot

If you’re looking for a winch for sale, you’ve come to the right place. This website offers winches and other tools that you can use to tow your vehicle. While you may be tempted to just buy any old one, you should consider a more powerful model. The Runva 9.5 XS Short Drum Rock Crawler offers nearly half the force of a standard winch. Its 5.8-horsepower motor provides 9500 pounds of pulling power. It’s made of steel and can be operated safely from a distance. This winch is normally $463, but Home Depot is offering it for $349 off the normal price until May 1.

Smittybilt

Smittybilt winches for sale have been improved in almost every area. This new line of winches features a Series Wound 6.6 HP motor, 3-Stage Planetary Gear System, and waterproof 500 AMP solenoid pack. This new line of winches is built to last for many years, and can easily handle the rigors of your toughest projects. Buying a new Smittybilt winch is an excellent way to improve the strength and functionality of your rig.

Aicrane

If you’re in the market for a 10 ton winch in Kenya, make sure to choose Aicrane. Aicrane winches are known for their tighter seals and superior interior components. Both of these factors are crucial to the performance and life of the winch. Read on for more information about Aicrane winches. We’ve provided the most helpful tips below. Choosing the right model can be a challenge – read on for some tips.

Hi-Lift

If you are looking for a cheap winch, consider a Hi-Lift. It works like a winch, but it moves your truck inches at a time instead of a full ton. You can use it to discourage vultures from perching on your truck, but it’s slow, sweaty, and not very versatile. In addition, it has a capacity of only 4660 pounds, and you must exert some force to extract it.

Superwinch

Whether you’re looking for a windlass winch for boat, car, or industrial application, Superwinch has it all. This high-tech manufacturer has been creating winches for over 40 years and continues to push the design envelope. Its winches are built to last and are designed with durability and performance in mind. They’ll keep you and your vehicle safe from danger with a single pull of the handle. Here’s a closer look at the Superwinch product range.

Rugged Ridge

Rugged Ridge winches are great for all sorts of off-road adventures. Many of the models feature tilt features, and most can be used with just about any type of off-road bumper. These winches are also suitable for over-riders. If you’re in the market for one, check out the options listed below. We recommend that you get a Rugged Ridge winch if you’re planning on spending a lot of time on your vehicle. Learn more: https://winchmachines.com/

Is a Portable Concrete Batch Plant the Right Choice for You?

If you’re in the market for a concrete batch plant, you may be wondering if a portable model is a right choice for you. Portable plants have many advantages over traditional stationary plants, but they also come with some drawbacks. So, which option is right for your business? Keep reading to find out.

The Functionality And Applications Of A Portable Concrete Batch Plant

A portable concrete batch plant is a machine that can be used to produce concrete on site. It is typically composed of a concrete mixer, an aggregate bin, a cement silo, and a control system. The plant can be assembled and disassembled as needed, making it an ideal choice for construction projects that require a lot of concrete. Portable batch plants are also much more efficient than traditional methods of producing concrete, such as mixing by hand or using a stationary concrete batching plant. For these reasons, they are often used on large-scale construction projects where time is of the essence.

The Components Of A Portable Batching Plant

A concrete batch plant is a machine that mixes water, sand, cement, and aggregate to create concrete. The concrete is then poured into molds or forms, and left to harden. Portable concrete batch plants are self-contained units that can be moved from one work site to another. These plants are typically used on construction sites, in homebuilding, and for repair work.

A portable concrete batch plant can be powered by electricity, gasoline, or diesel fuel depending on the model. The portable concrete batch plant will also have a mixer, an aggregate bin, a cement bin, and a water tank.

To operate the plant, the operator first adds water to the tank and turns on the mixer. Then they add sand, cement, and aggregate to the appropriate bins. The ingredients are mixed together in the correct proportions and poured into forms or molds. Once the concrete has hardened, it can be removed from the forms and used as needed. Portable concrete batch plants are a versatile and convenient option for construction projects of all types.

What Factors Should You Consider When Choosing A Portable Concrete Batch Plant Supplier?

When you are looking for a portable concrete batch plant supplier, there are a few things that you need to take into consideration. Firstly, you need to make sure that the supplier has a good reputation. You can do this by reading online reviews or asking for recommendations from people you trust.

Secondly, you need to make sure that the supplier offers competitive prices. This means that you should compare quotes from several different suppliers before making a decision. Finally, you need to make sure that the supplier offers good customer service. This means that they should be able to answer any questions you have and provide you with all the information you need. If you consider all of these factors, then you will be able to find a small concrete batch plant supplier that meets all of your needs.

Final Thoughts

A portable concrete batch plant is a great choice for projects that require on-site mixing of concrete. They are easy to set up and can be used in a variety of applications. The components of a portable batching plant include the mixer, aggregate bins, cement silo, water tank, and control panel. When choosing a supplier, it’s important to consider the factors that will have the biggest impact on your project. These factors include the size and type of mixer, the output capacity, portability, and electrical requirements. Get more details here: https://aimix.ke/ready-mix-plant/