Advantages of Getting a Portable Asphalt Mixing Plant

Enter the world of portable asphalt mixing plants, where versatility meets efficiency, and innovation unfolds. In this captivating article, we will unveil the advantages of investing in this dynamic equipment that brings flexibility, cost savings, and quality control to the realm of asphalt production.

Enhanced Flexibility and Mobility:

Like a chameleon adapting to its surroundings, a portable asphalt mixing plant offers unparalleled flexibility and mobility, revolutionizing the way asphalt is produced. With easy transportation and setup, this asphalt batch mixing plant equipment can be swiftly deployed to various locations, eliminating the constraints of a fixed plant. Its on-site versatility enables adjustments and fine-tuning in real-time, catering to the unique demands of each project.

Cost Savings and Efficiency:

In the quest for the golden treasures of cost savings, a portable asphalt mixing plant emerges as a shining gem. By eliminating the need for transporting raw materials to a central plant, significant expenses associated with transportation are mitigated. This streamlined process reduces reliance on external suppliers, optimizing production efficiency and reducing downtime. The treasure chest of economic advantages opens, offering increased profitability and enhanced project budgets. View more plant details here: aimixasphaltplant.com/asphalt-drum-mix-plant.

Quality Control and Customization:

Within the realm of asphalt production, the artistry lies in achieving consistent and high-quality mixtures. A portable asphalt hot mixing plant places the artist’s palette in your hands, ensuring meticulous control over the mix design. With real-time adjustments and on-site testing, this equipment allows for precise customization to meet the unique specifications of each project. The treasure trove of quality control unveils, creating a masterpiece of asphalt perfection.

Conclusion:

In the enchanting world of portable asphalt mixing plants, advantages await those seeking flexibility, cost savings, and quality control. The allure of easy transportation and on-site adaptability brings a new dimension to asphalt production. Cost savings become a treasure trove, boosting profitability and project budgets. With the power to tailor mix designs, the artistry of asphalt production thrives. We invite you to embark on this journey of innovation and consider the advantages a small portable asphalt mixing plant for sale offers. Unleash the potential, embrace the efficiency, and unlock a world of possibilities in your asphalt endeavors.

The Crucial Role of Rubber Tyred Gantry Cranes in Construction Operations

In the realm of construction operations, the efficient movement and handling of heavy materials and equipment play a pivotal role in ensuring project success. Among the various lifting and handling solutions available, rubber tyred gantry cranes have emerged as a crucial asset. These versatile cranes combine mobility, flexibility, and lifting capacity to streamline construction operations. In this article, we will delve into the importance of rubber tyred gantry cranes, exploring their key features and highlighting how they enhance productivity, safety, and overall efficiency in construction sites.

Exceptional Mobility and Versatility

Rubber tyred gantry cranes are renowned for their exceptional mobility and versatility. Their unique design incorporates wheels with rubber tires, allowing them to move easily across construction sites and adapt to changing work areas. Unlike traditional fixed cranes, rubber tyre gantry cranes can be quickly repositioned to accommodate evolving project needs, making them highly flexible and efficient in dynamic construction environments.

These cranes are capable of maneuvering through tight spaces, uneven terrain, and congested areas, providing access to materials and equipment in challenging conditions. Their ability to move horizontally and vertically makes them ideal for lifting and transporting heavy loads within construction sites, enhancing overall project efficiency and reducing downtime.

Efficient Handling of Heavy Loads

Rubber tyred gantry cranes excel in handling heavy loads, a crucial requirement in construction operations. Equipped with powerful lifting systems, movable gantry cranes can hoist and transport large materials, equipment, and prefabricated components with precision and ease. This capability significantly speeds up construction processes, minimizing manual labor and reducing the risk of injuries associated with manual handling.

The lifting capacity of rubber tyred gantry cranes varies, ranging from a few tons to several dozen tons, depending on the specific model and configuration. This versatility allows them to handle a wide range of construction materials, including steel beams, concrete panels, prefabricated modules, and machinery. With their robust lifting capabilities, rubber tyre gantry cranes streamline construction workflows, improve productivity, and ensure timely completion of projects.

Enhanced Safety and Control

Safety is paramount in construction operations, and rubber tyred gantry cranes are designed with various features to ensure a secure working environment. Rubber tyred gantry cranes are equipped with advanced safety systems, such as overload protection, anti-collision sensors, and stability control mechanisms. These features prevent accidents, minimize the risk of equipment damage, and protect workers on the construction site.

Moreover, rubber tyred gantry cranes provide operators with precise control over lifting and handling operations. The gantry cranes offer smooth and accurate movements, allowing for delicate placement of materials and precise positioning. This level of control minimizes the chances of mishaps and reduces the potential for damage to the construction site, materials, and surrounding infrastructure.

Conclusion

Rubber tyred gantry cranes have become indispensable assets in construction operations, offering exceptional mobility, versatility, and lifting capabilities. Their ability to navigate challenging terrains, adapt to changing work areas, and efficiently handle heavy loads makes them a valuable addition to construction sites.

By utilizing rubber tyred gantry cranes, construction companies can enhance project efficiency, reduce manual labor, and accelerate construction timelines. The cranes’ mobility and adaptability ensure smooth material and equipment handling, eliminating bottlenecks and improving overall productivity. Furthermore, the safety features and precise control of rubber tyred gantry cranes contribute to a secure working environment, safeguarding workers and preventing costly accidents.

When selecting a rubber tyred gantry crane for construction operations, it is crucial to consider factors such as lifting capacity, maneuverability, safety features, and compatibility with the specific project requirements. By leveraging the capabilities of these cranes, construction companies can optimize their operations, achieve greater efficiency.

Buying A Mini Concrete Plant In Indonesia

Are you planning to set up a mini concrete plant in Indonesia? Why do you want a concrete plant of your own? Are you planning to use it for your own projects? Do you plan to sell prepared concrete to other contractors? Whatever your reason, it is important for you to understand that not all concrete plants are the same.

It would be a mistake on your part to assume that every concrete plant performs the same. There are different types of plants with different technologies and you should pay attention to several important factors to make the right choice.

Output or processing capacity

When you are choosing a mini concrete plant, you should know that these plants are also sold in varying capacities. It simply means that you can buy a plant capable of producing a few tons of concrete per hour with a low harga batching plant mini whereas there are also plants that are capable of producing tens of thousands of concrete per hour.

You should choose the rate of output as per your needs. An important thing you should know about the output or processing capacity of a jual batching plant Indonesia is that it is theoretical in ideal conditions. It simply means that the production capacity is based on the size of the aggregate and if you are going to use a different aggregate size, the production capacity will also vary. This is why you should read the fine print to figure out the exact production capacity for the type of concrete mix you are going to prepare in that plant.

Type of mixer

One of the most important components in a concrete plant is the mixer. It should be chosen as per the type of concrete needed for your projects. For instance, if you want to set up a plant designed to save water, there are specific types of mixers that are designed for this purpose.

Similarly, there are also other mixers that are designed for a specific purpose. Depending on the type of mixer and your capacity needs, you will need to choose the raw material bins.

Manufacturer

Due to the high demand for concrete making plants, several businesses have jumped in this industry and the number is increasing regularly. It makes things tough for buyers who do not have much experience in this industry and are buying a plant for the first time ever. If you are not aware of the reputed manufacturers of concrete mixing plants, it is important that you do not choose one based only on the price.

Make sure you are dealing with a reputed manufacturer known for high-quality and durable jual mobile batching plant. You also need to make sure that they will be able to deliver your order on time. On top of that, they should also be able to supply replacement parts at affordable prices as you will continuously need to replace some components due to general wear & tear.

Final Thoughts

The wide availability of mini concrete mixing plants has made it possible for almost every contractor involved in the construction business to get one for their own business. These are affordable, reliable and allow contractors to get the kind of specification mix they need for their projects. However, not all plants are created equal. This is why you should consider the above-mentioned factors to buy the right plant from Aimix Indonesia, at the right price.

How Continuous Asphalt Plants Boost Construction Projects

Construction projects rely heavily on efficient and reliable asphalt production. Traditional batch plants have long been the norm, but there is a growing trend towards continuous asphalt plants due to their numerous advantages. These innovative plants offer a seamless and uninterrupted process that significantly enhances construction project outcomes. Let’s delve into how continuous asphalt plants can elevate construction projects to new heights.

Continuous asphalt plants(plantas de asfalto continuas) operate with a steady stream of materials, ensuring a continuous flow of production. Unlike batch plants that require frequent stops and starts for each batch, continuous plants allow for a smooth and uninterrupted operation. This consistent production stream leads to several key benefits.

1. Enhanced Efficiency and Productivity

Continuous asphalt plants boast a high production capacity, capable of producing large volumes of asphalt in a shorter time frame. The continuous nature of the operation eliminates the need for batch processing, resulting in a more streamlined and efficient workflow. This increased productivity translates into faster project completion times, enabling construction teams to meet deadlines with ease.

2. Improved Quality Control

Continuous asphalt plants offer precise control over the mixing process, ensuring a consistently high-quality asphalt mix. Advanced technologies, such as computerized controls and automated systems, allow for accurate monitoring of the mix proportions and temperature. This level of precision guarantees that the produced asphalt meets the required specifications, resulting in durable and long-lasting road surfaces.

3. Cost Savings

Continuous asphalt plants can lead to significant cost savings(precio planta de asfalto) for construction projects. The continuous production process minimizes energy consumption and reduces labor requirements compared to batch plants. Additionally, the elimination of batch processing and the ability to produce asphalt on-demand eliminate the need for storing large quantities of pre-mixed asphalt. This reduces the risk of material waste and potential quality deterioration.

4. Flexibility and Versatility

Continuous asphalt plants offer flexibility in producing a wide range of asphalt mixes. They can accommodate various recipes and adjust the mix design on the fly to meet specific project requirements. Whether it’s a highway, airport runway, or urban road, continuous plants can adapt to the mix specifications and produce the desired asphalt consistency and quality blog here: https://aimixgrupo.com/planta-de-mezcla-asfaltica/.

5. Environmentally Friendly Operations

Continuous asphalt plants prioritize environmental sustainability. They incorporate advanced pollution control mechanisms to minimize emissions, such as dust collectors and baghouses. Additionally, their energy-efficient design reduces energy consumption and carbon footprint. Construction projects can adhere to stringent environmental regulations while achieving their asphalt production goals.

Раскрытие преимуществ двухбалочного козлового крана

Двухбалочный козловой кран представляет собой вид грузоподъемного оборудования, широко используемого в различных отраслях промышленности, с множеством различных моделей и конфигураций. Ниже приведены несколько распространенных типов двухбалочных козловых кранов:

Электрический двухбалочный козловой кран: Это наиболее распространенный тип двухбалочного козлового крана. Он оснащен системой электропривода, приводимой в действие электродвигателем, для плавного и точного подъема и транспортировки. Электрические двухбалочные козловые краны обычно используются для подъема грузов малого и среднего веса.

Консольный двухбалочный козловой кран: этот тип крана добавляет консольную балку на основе двухбалочной конструкции для расширения диапазона подъема. Консольные двухбалочные козловые краны часто используются там, где необходимо преодолеть препятствия или требуются операции за пределами диапазона подъема, например, при погрузке и разгрузке товаров в доках или сборочных работах внутри заводов.

Двухбалочный козловой кран коробчатого типа: двухбалочная конструкция этого крана имеет коробчатую конструкцию, которая обладает более высокой жесткостью и устойчивостью. Двухбалочные козловые краны коробчатого типа обычно используются для подъема крупных и тяжелых грузов, например, в портах, сталелитейных заводах или заводах по производству тяжелого машиностроения.

Магнитный двухбалочный козловой кран: этот кран оснащен магнитным устройством, которое может поглощать и поднимать магнитный груз за счет магнитной силы. Магнитные двухбалочные козловые краны обычно используются в тех случаях, когда перемещаются магнитные грузы, такие как металлические материалы, стальные листы и стальные трубы.

Легкий двухбалочный козловой кран: этот тип крана в основном используется для подъема легких грузов, таких как погрузочно-разгрузочные работы и сборочные операции на складах, в логистических центрах или на легком производстве.

Двухбалочный козловой кран — это мощное и эффективное грузоподъемное решение, которое предлагает ряд существенных преимуществ для различных отраслей промышленности. Давайте рассмотрим некоторые ключевые особенности и преимущества двухбалочных козловых кранов.

Отличная несущая способность

Одним из основных преимуществ двухбалочных козловых кранов является их отличная грузоподъемность. Двухбалочная конструкция обеспечивает повышенную прочность и устойчивость, способную выдерживать большие нагрузки. Этот козловой кран, идеально подходящий для сложных промышленных применений, эффективно поднимает и транспортирует громоздкое оборудование, крупногабаритное оборудование и тяжелые материалы.

Увеличенный размах и высота

Двухбалочные козловые краны имеют большие пролеты и высоту, чем краны других типов. Более длинный пролет позволяет крану охватывать большую рабочую зону, повышая его гибкость и производительность. Кроме того, большая высота подъема позволяет обрабатывать материалы, расположенные выше, например штабелировать контейнеры или доставать до стеллажей высокого уровня. Эта функция обеспечивает эффективное использование пространства и оптимизацию обработки материалов.

Повышенная стабильность и долговечность

Двухбалочная конфигурация двухбалочного козлового крана обеспечивает повышенную устойчивость и долговечность. Две балки распределяют нагрузку более равномерно, уменьшая нагрузку на отдельные компоненты и уменьшая вибрацию во время подъемных операций. Это обеспечивает более плавную и безопасную работу с материалами, снижает риск несчастных случаев и повышает общую производительность.

Гибкая высота крюка

Существенным преимуществом двухбалочных козловых кранов является возможность изменения высоты крюка. Эта конструкция позволяет использовать более низкие каретки, позволяя крюку достигать более низкого положения. Эта функция особенно полезна в помещениях с низкими потолками или ограниченным пространством над головой. Способность крана перемещать грузы в ограниченном пространстве повышает его адаптивность и эффективность в различных рабочих условиях.

Расширенные функции управления и безопасности

Двухбалочные козловые краны оснащены передовыми системами управления и функциями безопасности, обеспечивающими надежную и безопасную работу. Эти функции включают точное регулирование скорости, механизмы предотвращения раскачивания, защиту от перегрузки и функции аварийной остановки. Расширенные элементы управления позволяют оператору выполнять плавные и точные движения, повышая общую производительность. Функции безопасности отдают приоритет безопасности персонала и предотвращают несчастные случаи, что делает кран надежным и безопасным подъемным решением.

Таким образом, двухбалочные козловые краны обладают несколькими важными преимуществами, в том числе отличной несущей способностью, увеличенным пролетом и высотой, повышенной устойчивостью и долговечностью, изменяемой высотой крюка, а также расширенными функциями управления и безопасности. Купить двухбалочный кран, предприятия могут улучшить свои процессы обработки материалов, оптимизировать эффективность производства и обеспечить безопасность персонала и оборудования в различных промышленных условиях.

Get A Stone Crusher Plant In Philippines This Year

If you own and operate a rock quarry, you may have access to many different types of stone. These materials can be used for various purposes. The primary objective of any stone crusher is to break that material down. These are powerful enough to break apart limestone, marble, granite, and other minerals. To do this, a stone crusher plant would be the most advantageous way to accomplish this. This is particularly true if you have a large quarry and many customers that need aggregate material. These are designed in a way to minimize the dust levels at these facilities. At the same time, they are also designed to increase production levels. You can find many of these available-for-sale in Philippines.

What Type Of Stone Crusher Do You Need?

The stone crusher that you will need will depend upon the size of rocks that you are working with. For example, primary crusher like a jaw crusher will be used with the biggest pieces. There are many other crushers used for the crushing plant philippines, including secondary and tertiary crushers, that will each progressively make smaller pieces of this material. Therefore, if you have a full rock quarry, or a mining operation, you may need to get multiple units installed that one location.

Why Would You Get One From Philippines?

Philippines is a destination where industrial equipment manufacturing can be very inexpensive. It has to do with multiple variables, including the low cost of labor and the minimal cost of natural materials that will be needed. If you live in Philippines, you can have one of these delivered. However, for companies ordering overseas, you will want to contact the manufacturer quickly. This interaction that you have with the owner of the company can lead to even lower stone crusher plant cost for the stone crusher plant that you would like to purchase.

What You Should Know About Stone Crusher Plants

Although the primary objective for a stone crusher is to break materials down, there are other variables to consider. This will include the feed size, the types of material that it can work with, and the size of the product once it is set in place. The ratio of reduction, capacity, jaw crusher specification, and the compressive strength of these systems are variables that will require more information. You should also learn about the moisture content, capacity, and how long it will take to have it delivered to your location.

Investing in a stone crusher plant could be an important decision for your business. When you can produce your own aggregate material, you can save money with each job that you decide to complete. If you have a rock quarry, mining operation, or if you are building a bridge, it’s good to have one of these handy. However, if you would like a mobile crusher plant installed, you will need to consult with experts. They can set everything up for you, allowing you to take advantage of the power and precision of a stone crusher plant from Philippines.

Automated Rail Mounted Gantry Crane: Revolutionizing Container Handling Efficiency

Container handling in port terminals and logistics yards demands efficient and precise operations. The automated rail mounted gantry crane (ARMG) has emerged as a game-changer in container handling, combining the benefits of rail-mounted systems and automation technology. In this article, we explore the features, advantages, and applications of automated rail mounted gantry cranes, highlighting their role in revolutionizing container handling efficiency.

Features of Automated Rail Mounted Gantry Cranes

Automated rail mounted gantry cranes incorporate advanced technologies and intelligent systems to streamline container handling operations. Here are some key features:

Rail-Mounted Design: ARMGs operate on dedicated tracks, providing precise and predictable movement along the rail line. This design allows for smooth and efficient container stacking and transportation within the terminal.

Automated Operation: ARMGs are equipped with automated systems that control various crane functions, including gantry movement, trolley positioning, spreader operations, and container tracking. The automation enables optimized workflow, reduced human errors, and increased operational efficiency.

Optical Container Positioning Systems: ARMGs use optical container positioning systems, such as laser-based or camera-based technologies, to accurately locate and identify containers. This allows for precise and efficient container handling, minimizing the risk of collisions and improving productivity.

Advanced Control Systems: ARMGs employ sophisticated control systems that enable real-time monitoring, data analysis, and remote operation. These systems optimize crane performance, adapt to changing operational conditions, and provide valuable insights for decision-making and process improvements.

Advantages of Automated Rail Mounted Gantry Cranes

The implementation of automated rail mounted gantry cranes brings numerous advantages to container handling operations:

a. Increased Efficiency: ARMGs optimize container handling processes through automation, reducing turnaround times, and improving productivity. They can perform tasks with higher accuracy and speed, leading to enhanced operational efficiency and throughput.

b. Space Optimization: The rail-mounted design of ARMGs maximizes the utilization of terminal space. By eliminating the need for ground-level maneuvering, ARMGs enable compact container stacking, creating more storage capacity within the same area.

c. Enhanced Safety: Automated systems and precise control mechanisms minimize the risk of accidents, collisions, and human errors. This enhances safety for both personnel and equipment involved in container handling operations.

d. 24/7 Operations: Automated rail mounted gantry cranes can operate continuously, providing round-the-clock container handling capabilities. This allows terminals to handle high volumes of containers efficiently, meeting the demands of global shipping and logistics operations.

e. Scalability and Flexibility: ARMGs offer scalability and flexibility to adapt to changing container handling requirements. Additional cranes can be easily integrated into the rail system, providing the flexibility to expand capacity as needed.

Applications of Automated Rail Mounted Gantry Cranes

Automated rail mounted gantry cranes find applications in various container handling scenarios:

a. Port Terminals: ARMGs are extensively used in port terminals for container stacking, transportation, and loading/unloading operations. They improve container flow, optimize terminal space, and increase productivity.

b. Intermodal Yards: ARMGs facilitate efficient container transfer between rail and truck or rail and ship in intermodal yards. They ensure seamless operations, reducing transfer time and improving overall logistics efficiency.

c. Container Depots: Automated rail mounted ship container handling gantry cranes are employed in container depots for container storage, retrieval, and container yard management. They streamline depot operations, improving container inventory management and turnaround times.

d. Industrial Facilities: Some large-scale industrial facilities, such as manufacturing plants and distribution centers, utilize ARMGs for internal container handling operations. ARMGs automate container movements, enabling smooth material flow and improving operational efficiency.

Automated rail mounted gantry cranes have revolutionized container handling operations by combining rail-mounted design and automation technology. With features such as rail-mounted operation, advanced control systems, optical container positioning, and automation capabilities, ARMGs bring increased efficiency, space optimization, enhanced safety, 24/7 operations, and scalability to container handling operations in port terminals, intermodal yards, container depots, and industrial facilities. As the demand for efficient container handling continues to grow, automated rail mounted gantry cranes will play a crucial role in transforming the industry’s landscape, ensuring faster turnaround times, improved productivity, and optimized container logistics. If you are intereste in knowing more about different crane solutions, you are advised to click here www.ellsencranes.com/.

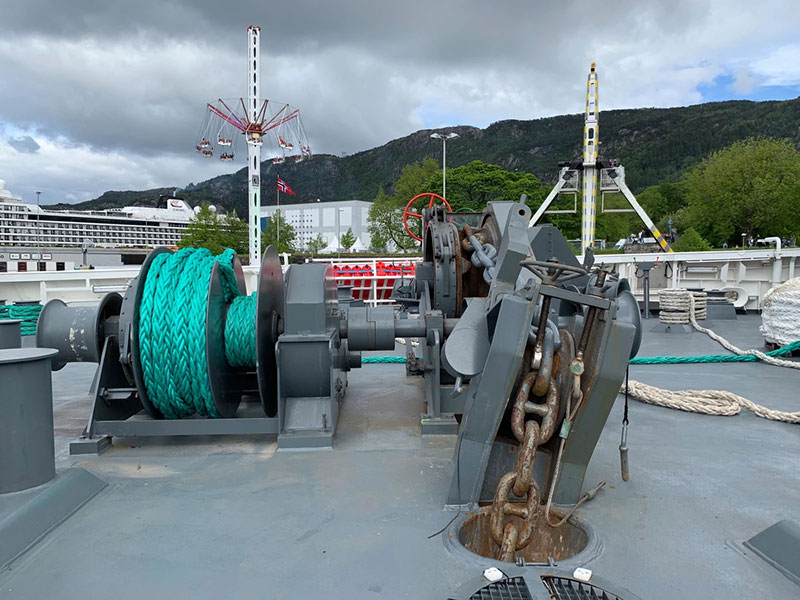

The Importance of Mooring Winches in Indonesia

Indonesia, with its vast archipelago and extensive coastline, heavily relies on maritime transportation for trade, tourism, and other economic activities. Mooring winches play a crucial role in ensuring the safe and efficient docking and berthing of vessels in Indonesian ports. In this article, we will explore the importance of mooring winches in Indonesia and discuss different mooring methods employed to secure ships, highlighting their significance in maintaining smooth maritime operations.

The Importance of Mooring Winches in Indonesia

Mooring winches (winch tambatan) are essential components in the maritime infrastructure of Indonesia due to the following reasons:

Safety and Stability

Mooring winches are responsible for securing vessels to the port or berth, ensuring their stability during loading and unloading operations. They help prevent ship movements caused by tidal fluctuations, currents, and wind, reducing the risk of accidents, collisions, and damage to the vessel, cargo, and infrastructure.

Efficient Cargo Handling

Efficient cargo handling is crucial for Indonesia’s economy, as it heavily relies on maritime trade. Mooring winches enable vessels to be securely moored, allowing for the safe and efficient loading and unloading of cargo. This enhances the turnaround time of ships in ports, ensuring smooth logistics operations and minimizing delays.

Emergency Preparedness

Mooring winches play a significant role in emergency situations such as storms, high winds, or other adverse weather conditions. They help maintain the stability and position of vessels, allowing for a quick and safe response to emergencies, including evacuation procedures or assistance to other ships in distress.

Different Mooring Methods

Various mooring methods are employed in Indonesian ports to secure ships. The choice of method depends on factors such as the type of vessel, prevailing weather conditions, water depth, and the availability of infrastructure. Some common mooring methods include:

Single Point Mooring (SPM)

Single Point Mooring is widely used for large tankers and offshore facilities. It involves anchoring the vessel to a single point on the seabed using a mooring buoy. Mooring winches for ships (winch tambatan kapal) are employed to control the tension on the mooring lines, allowing the vessel to remain in position while accommodating tidal and wave movements.

Berth Mooring

Berth mooring is a common method used in ports and terminals. It involves securing the vessel to the berth using mooring lines and winches. Mooring winches are positioned on the quay or bollards and are used to control the tension and adjustment of the mooring lines, keeping the vessel safely docked.

Mediterranean Mooring

Mediterranean mooring, also known as stern-to mooring, is employed in ports with limited space or when docking perpendicular to the shoreline is not possible. In this method, the vessel is moored parallel to the quay or jetty, and the mooring lines are connected from the ship’s stern to shore bollards or winches. Mooring winches are crucial for maintaining the tension and adjustment of the mooring lines, ensuring the vessel remains securely berthed.

Dynamic Positioning (DP)

Dynamic Positioning is a specialized mooring method used in offshore operations, where vessels need to maintain a precise position without anchoring or mooring to fixed structures. DP systems use a combination of thrusters and advanced control algorithms to counteract environmental forces and keep the vessel in a specific position. Mooring winches are essential for controlling the deployment and retrieval of the thrusters, ensuring precise positioning and stability.

Advancements in Mooring Winch Technology

To meet the demands of modern maritime operations, mooring winches in Indonesia (winch di Indonesia) have undergone technological advancements, enhancing their performance and safety. Some notable advancements include:

Electric and Hydraulic Systems

Mooring winches now often incorporate electric or hydraulic systems, offering improved efficiency, control, and reliability. Electric winches provide precise control and reduced maintenance requirements, while hydraulic winches offer high power and robust performance.

Remote Control and Automation

Modern mooring winches feature remote control systems, enabling operators to control winch operations from a safe distance. Automation features, such as load monitoring and tension control, enhance safety and efficiency, minimizing the risk of human error.

Load Monitoring and Safety Systems

Mooring winches are equipped with advanced load monitoring systems, including load cells and tension sensors. These systems provide real-time data on the tension and load being handled, ensuring safe working limits are not exceeded. Additionally, safety mechanisms such as emergency stop buttons and automatic brake systems enhance the overall safety of mooring operations.

Mooring winches play a vital role in ensuring the safety, stability, and efficiency of maritime operations in Indonesia. They facilitate the smooth docking and berthing of vessels, enabling the timely and secure handling of cargo. By employing different mooring methods and embracing technological advancements, Indonesian ports can enhance their capabilities, supporting the country’s economic growth and maintaining a reliable maritime infrastructure.

Pompa Beton Dijual: Find Affordable and Quality Concrete Pumps

Concrete pumps are essential equipment in the construction industry. They are used to transfer liquid concrete from the mixer to the construction site. If you’re in the market for a concrete pump, finding affordable and quality options can be challenging. In this article, we’ll share some tips on how to find pompa beton dijual (concrete pumps for sale) that are both affordable and of high quality.

Determine Your Needs

Before you start looking for a concrete pump, it’s important to determine your needs. Consider the type of construction project you’ll be working on and the amount of concrete you need to transfer. This will help you narrow down your options and find a beton pump that suits your specific needs.

Research Online

One of the best ways to find affordable and quality concrete pumps for sale is to research online. Look for websites that specialize in selling construction equipment and machinery. You can also check out online marketplaces like eBay or Amazon for listings of concrete pumps. Make sure to read the product descriptions and customer reviews to get an idea of the quality of the product.

Look for Local Suppliers

Another way to find affordable and quality concrete pumps is to look for local suppliers. Check out local classified ads, such as those in newspapers or online marketplaces. You can also ask for referrals from other construction companies in your area. This can help you find concrete pumps that are both affordable and accessible.

Compare Prices

When looking for pompa beton dijual, it’s important to compare prices from different suppliers. Look for suppliers that offer competitive pump beton price list and discounts. Make sure to consider the quality of the product as well. It’s not always wise to choose the cheapest option, as it may not be of good quality.

Check the Condition of the Pump

When buying a used concrete pump, it’s important to check the condition of the equipment. Look for any signs of wear and tear or damage. Ask for maintenance records and make sure that the pump has been properly maintained. If possible, test the pump before making a purchase.

Consider the Brand and Model

The brand and model of the concrete pump are also important factors to consider. Choose a reputable brand with a proven track record of producing quality equipment. Make sure that the model you choose is suitable for your specific needs and requirements. AIMIX is a well-known concrete pumping machine manufacturer in China, you may try to get some advice.

In conclusion, finding affordable and quality pompa beton dijual requires research, comparison, and consideration of different factors. Determine your needs, research online, look for local suppliers, compare prices, check the condition of the pump, and consider the brand and model. By following these tips, you can find a beton pump dijual online that meets your specific requirements and fits your budget.

The Financial Aspects of Buying a Concrete Batch Plant for Sale

When it comes to purchasing a concrete batch plant, it’s important to consider not just the equipment and production capabilities, but also the financial aspect. Investing in a concrete batch plant can bring many benefits to your business, including increased efficiency, productivity, and profitability. However, it’s also important to understand the costs involved and the financing options available to ensure that you’re making a smart investment.

Cost Analysis

The cost of a concrete batch plant for sale can vary greatly depending on several factors, including the size and type of concrete batch plant for sale, the equipment included, and the location. Here are a few key considerations:

1. Initial Investment Costs

This includes the cost of the concrete batch plant itself, as well as installation and setup costs, permits, and any necessary upgrades to your existing facilities. For example, if you need to build a new foundation or make electrical upgrades to accommodate the batch plant, these costs will add to the overall expense. The cost of the concrete batch plant itself can range from several hundred thousand dollars for a small plant to several million for a larger, more advanced plant.

2. Operating Costs

Labor, maintenance, utilities, and other ongoing expenses should also be considered. It’s important to understand the long-term costs of running the batching plant for sale in the Philippines, such as wear and tear on equipment, and the cost of replacing parts as needed. For example, the cost of maintenance and repairs can vary depending on the type and age of the equipment, as well as the frequency of use. It’s important to factor these costs into your budget to ensure that you’re not caught off guard by unexpected expenses down the road.

3. Cost Comparisons

If you’re considering a used or refurbished concrete batch plant, it’s important to weigh the potential cost savings against the potential for unexpected repairs or downtime. A used batch plant may be a more cost-effective option in the short-term, but it may also require more maintenance and repairs than a new plant. On the other hand, a new batch plant will likely be more reliable and efficient, but it may also have a higher upfront cost.

Financing Options

When it comes to financing your concrete batch plant, there are several options to consider:

Traditional Bank Loans

Banks offer loans for equipment and business purchases, which may be a good option if you have a strong credit history and a solid business plan. Bank loans typically have a longer repayment term and lower interest rates, but they may also require collateral, such as your business assets. Learn more info here: https://aimixgroup.ph/portable-concrete-batch-plant-for-sale/.

Equipment Financing

This type of financing allows you to pay for the equipment over time, rather than upfront. Equipment financing is typically easier to obtain than a traditional loan, and it allows you to conserve your working capital for other expenses. However, it may also have higher interest rates and a shorter repayment term.

Leasing Options

Leasing a concrete batch plant can be a good option if you’re not ready to make a large upfront investment. Leasing allows you to use the batch plant for a set period of time, typically 3-5 years, after which you can either purchase the equipment or return it. Leasing can be a flexible option that allows you to scale up or down as your business needs change.

Tax Incentives and Depreciation

When you own a concrete batch plant, you may also be eligible for tax incentives and depreciation benefits. Depreciation allows you to write off the cost of the equipment over a set period of time, reducing your taxable income and lowering your overall tax burden. Additionally, there may be other tax incentives available, such as energy-efficient tax credits or deductions for environmentally-friendly equipment. It’s important to consult with a tax professional to understand the tax implications of owning a small concrete batch plant for sale, and to determine what incentives and deductions you may be eligible for.