Are you planning to buy a jaw crusher? A jaw crusher is widely used in mines and other businesses where a powerful machine is needed to make quick work of huge stones in order to crush them into more manageable chunks. A jaw crusher is typically used as a primary crusher that breaks down big pieces of stones into manageable pieces which are then fed into secondary crushers to bring them down to the size as per the requirements.

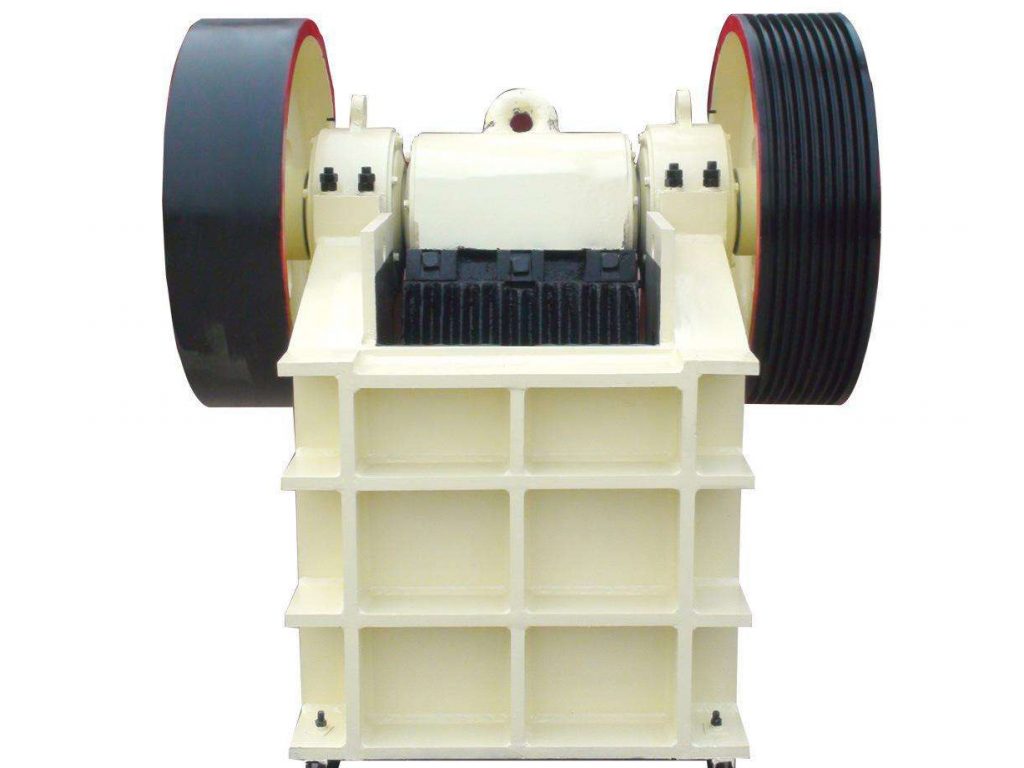

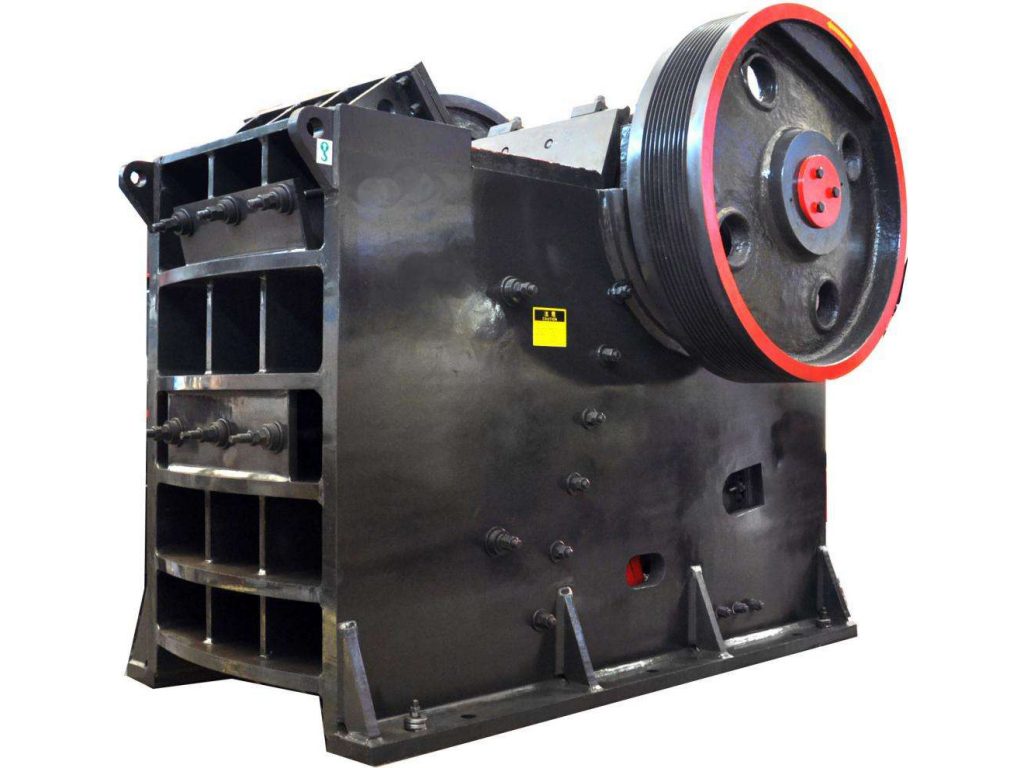

In principle, all jaw crushers are the same as every machine has a stationary jaw and a moving jaw. The moving jaw pushes the stones against the stationary jaw at high pressure and this pressure ultimately breaks down the rocks into smaller pieces. However, there are many different types of jaw crushers and here is what you need to know in order to choose the right one for your business.

First and foremost, you should know that jaw crushers are widely used for coarse crushing as well as fine crushing(trituración gruesa y trituración fina). One of the most important parameters you need to look at is the type of materials that are going to be crushed in the machine. Different types of crushers are designed to be used for crushing of different types of materials which means you can’t really use a single piece of machinery in various mines.

Various properties of the minerals such as humidity, structure, hardness and production environment(entorno de producción), among other things, are typically used to choose the right jaw crusher. Another important thing that matters is the crushing capacity and production rate. If you are processing a huge amount of stones, you will need to invest in a machine with much higher capacity. Needless to say, higher capacity comes at a higher price. Do not make the mistake of choosing too much capacity as it typically lowers the operational efficiency and increases your overall production costs. Therefore, choose a capacity that is just ideal for your current as well as near-term future requirements.

When it comes to operational expenses, you need to look at the efficiency, power consumption, and crushing yield among other things. One of the most overlooked things in this business is the availability of spare parts. Some businesses make the mistake of buying a crusher that is available at a low initial cost but the manufacturers usually make money by supplying the replacement parts at a much higher price than average. Since these are proprietary components, buyers are forced to keep buying those components from the manufacturer itself. Therefore, you to pay special attention to the affordable availability of spare parts to keep your operational costs to the minimum.

When you start researching suppliers, you will find that there are many companies involved in this business but not every company has excellent reputation when it comes to quality of the machines as well as after sale service. You want to deal with a company that is known for quality of its products as well as after sales service. Therefore, choose a manufacturer like AIMIX Crusher(AIMIX Trituradora) only after carefully researching their reputation among their clients.

To conclude, a jaw crusher is widely used in the mining industry to break down big stones into smaller pieces. However, not all the crushers are the same. There are different types of crushers and the above-mentioned tips should help you in choosing the right one as per your business requirements.