There are two kinds of Asphalt Mixing Plants: batch type and continuous type. Both have different features. Batch type plants stock the aggregates in different compartments and are equipped with a control panel. Continuous type plants screen the aggregates before adding bitumen and filler material. The mixture is then discharged into a truck or a storage silo. The control panel is designed to monitor all the activities of the plant and gives a report on important parameters.

Mobile Asphalt Plants

Mobile asphalt mixing plants are a great option for small and medium scale road construction projects. They are easy to transport and erect, with a low cost of operation. They have advanced features such as high-performance motors, accurate fabricated dryers, and segmented drive sprockets.

These mixing plants are designed to handle a variety of tasks, from small projects to large road construction. They can be used for a variety of applications and are RTO-approved. They provide seamless performance with minimum inputs. They can be used in asphalt plant projects of all types. Their compact designs make them easy to transport and install.

Mobile asphalt mixing plants are the most portable type of asphalt mixing plants, featuring modular construction and transport frame chassis. This allows for easier transport and less space consumption. They can be quickly assembled and disassembled, and their mixing capacity is ten to fifty tons. The mobile units are ideal for highway and city road construction, as well as port construction.

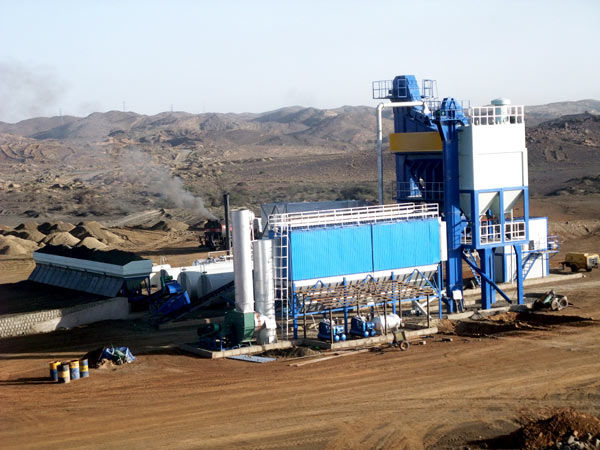

Stationary Asphalt Plants

Stationary asphalt mixing plants are designed for large-scale production of asphalt. They can prepare large amounts of quality asphalt mix in a short period of time, with reduced energy cost. Furthermore, stationary plants tend to have longer service life compared to mobile ones. As such, they are preferred in situations where a high-quality asphalt mix is required on a regular basis.

Stationary asphalt mixing plants are available in various capacities, ranging from 40 to 320 tons per hour. They are generally used in road construction and dam construction. This type of asphalt plant in the Philippines is known for its consistent performance, reliability, and ease of installation.

Drum Mix Plants

A drum mix plant is a powerful asphalt mixing machine. Unlike batch plants, which switch between different mix recipes periodically, drum mix plants produce a consistent asphalt mix in one continuous process. They are typically skid-mounted or portable and range from 120 to 500 tons per hour. Their simple design, high specific mixing capacity, and environmental compliance make them an ideal choice for asphalt producers of all sizes. Here’s a brief explanation of how they work.

A drum mix plant can produce more asphalt per hour than a batch plant. The process involves heating aggregates and homogeneously mixing them with a certain amount of Bitumen and filler. The mixture is then continuously dispensed into a truck or storage silo. Depending on the specifications of the plant, the capacity can range from 20 to 120 tons per hour (TPH). Higher capacities can also be purchased for specific projects.

Continuous Drum Mix Plants

When deciding between continuous drum mix plants for asphalt and batch plants, consider your business’ needs. If your asphalt projects typically require large volumes of material, continuous plants are often a better choice. If your projects involve a high amount of reclaimed asphalt pavement (RAP), a continuous plant will be more efficient.

Continuous drum mix plants for asphalt start by feeding cold aggregates into feeding bins. Typically, a drum mix plant has three or four bin feeders. Aggregates are loaded into different bins according to size and grade, and each bin has movable gates. Aggregates then travel over a long conveyor belt to a scalping screen. In addition to a scalping screen, modern asphalt drum mix plants use a triple heat transfer system to transfer heat from the heating unit to the aggregates. The triple heat transfer system ensures total transfer of heat to the aggregates, using three different heat transfer methods: conductive, connective, and radiation. Learn more information about the asphat plant: https://aimixphilippines.ph/small-portable-asphalt-plants-for-sale/.

Continuous drum mix plants for asphalt are a reliable option. They can be installed in a short time and are designed to handle high volumes of asphalt. Each drum plant contains multiple components, including cold feeder bins, weighing conveyors, and bitumen tanks. They also feature an adjustable burner and control cabins.

Air Pollution Control Devices

Asphalt mixing plants create particulate matter that affects the quality of air in the surrounding area. In order to meet state and local regulations, asphalt plants must install air pollution control devices. These devices can either be new or retrofitted to existing asphalt plants. There are two types of pollution control devices available: a primary dust collection system and a secondary dust collection system. Both systems remove a high percentage of the pollutants created by the asphalt hot mix plant.

In addition to installing these systems, the operator should also consider air pollution control standards. Proper maintenance can make a big difference when it comes to the quality of hot mix asphalt. For instance, dirty burners can release excessive smoke into the atmosphere and cause other combustion by products. The air-to-fuel ratio of a burner is important to achieve the lowest possible air pollution levels.