A Closer Look at Double Girder Overhead Cranes

The double-girder overhead cranes are the best heavy-duty overhead lifting solutions. The dual-girder crane design consists of two parallel girder bridges going through each platform of a double girder overhead arrangement. One bridge connects the two platforms, and the other one attaches to the opposite platform. In the double-girder design, the primary movement is from left to right.

The main advantage of this system is that it gives good leverage. It allows for greater speed compared to a single-girder design and offers better stability. While there are other types of overhead cranes, such as the four-girder and five-girder design, most construction companies would find the dual-girder model (modelo de doble viga) more than adequate.

Multiple girder overhead cranes can be divided into three different categories depending on the weight and the number of pillars in the structure. The single girder system is the most common type of overhead cranes, consisting of two parallel girder structures joined together using four girder beams. The two beams are fixed to the structure by means of the three primary columns. This system has the least number of beams per girder, allowing for light to moderate weight to be supported.

A double girder overhead crane consists of three beams fixed at an angle, and the angle is set by the center beam. Each of the four beams supports a heavier weight than that of the three beams, resulting in greater stability and leverage.

The four-girder design is also known as the “triangle design.” This design requires three beams to support the weight of the structure, allowing the three beams to move vertically through the structure. The triangle design is commonly used in large industrial or commercial buildings and is the only design where the center beam moves vertically.

There is also the five-girder design, which consists of four beams, but only one is fixed in position. The other two beams move vertically, with the middle beam resting on top of the floor joists. Both designs are capable of supporting high loads and provide a high degree of stability and leverage. This design offers the most balance and stability, allowing for greater leverage. These types of crane are used in most residential and commercial buildings.

Even if some models can lift heavier loads than the double-girder overhead crane, you might still be better off choosing this particular model if it perfectly fits your specific lifting requirements. Also, the double-girder overhead crane is often considered the most efficient of all types of overhead lifting solutions. The reason is that it offers adequate lifting capacity while maintaining a relatively low operating cost.

It pays to know that you can add extra features to improve the double-girder overhead crane’s functionality. Some of the most popular additions include walkways, lights, and operator cabs.

When you’re all set to purchase this equipment, take time to review the products from multiple manufacturers. This gives you an idea of how much you would need to spend while also evaluating which company, maybe AICRANE can provide the best after-sales customer service. You can find a reliable product here https://aicrane.cl/puente-grua-birriel/.

Gantry Cranes: Important Safety Considerations To Keep In Mind

Safety is going to be essential when it is time to use a new gantry crane (nuevo grúa pórtico). You want to have a set checklist in your mind to ensure things work out as planned.

Here are the details that matter the most for your gantry crane and how well it works.

Spacing

The first detail is going to involve spacing with the gantry crane. You want to make sure there is enough clearing space for the load to be moved from point A to point B. If not, the gantry crane isn’t going to work the way it is supposed to and will become a safety hazard at the same time.

There has to be enough clearing space for the crane to work the way it is supposed to.

This includes making sure there is nothing in the way of the gantry crane when it is working.

Power Output

The power output has to be kept in mind when it comes to safety with a gantry crane. You want to ensure it is able to handle the load that is being set up. Otherwise, it is going to break down and/or not work the way you want it to.

There are several hurdles that can pop up and this is one of them.

The power output metrics should be in the back of your mind when it comes to safety. You need to know what you are dealing with and how the gantry crane is going to work once it is put to use.

Rope Condition

Go with something that is made the right way because that will matter a lot over the long-term. You want to think about the ropes because they are going to hold the load as soon as it has been readied. You don’t want a situation where the ropes snap under the weight of the load.

You want to make sure the ropes have been tested and aren’t wearing down.

Sometimes, the ropes tend to break down especially if you have been pushing the capacity for months or years. It’s important to keep an eye out for this at all times.

Structural Details

How strong is the gantry crane when it comes to holding the load that is being asked of it to manage. There are several details that are going to matter including the joints. The gantry crane shouldn’t get to the point where it isn’t structurally sound. The goal is to make sure everything is resilient as that is going to go a long way in managing what you are doing over the long haul.

When it comes time to determine whether or not the crane is safe, you will want to test these structural details every step of the way.

These are the main qualities to think about when it comes to creating a little safety checklist. You never want a situation where the gantry crane starts to break down as that can happen in some situations. Go with a high-grade solution that will work well and has been tested. So for more details, just enter ellsengruaportico.es

Why You Should Consider Investing In A Single Girder Overhead Crane

Are you trying to decide between a double or single girder overhead crane? While both types of cranes offer advantages, you may find that investing in a single girder crane is a better use of your money. Read on to find out why a crane like this can be such a smart purchase.

It’s The Most Affordable Option

It’s likely that you’ll want to limit what you spend on a purchase like this, especially because gantry cranes can be so expensive. If you want to get more out of your budget, you’ll want to focus on single girder cranes (puentes grúa monorraíles).

These cranes tend to be priced very reasonably, especially when compared against similar options on the market. If you’re interested in getting more value for the money that you spend, you should consider buying a crane like this instead of splurging on a more expensive option.

It Can Be Installed Quickly

Once you purchase a single girder crane, it won’t be long before it’s fully installed. That means you’ll be able to start using the crane right away. Some types of cranes are more difficult to install, and they can be challenging removing as well. If you invest in a crane like this, it can be a struggle to move it to different job sites.

Your time has value, and when you’re looking at the cost (costo) of a crane, one of the things you’ll want to consider is how long it will take to set everything up. With a single girder crane, you’ll be able to take care of this in no time.

Your Freight Costs Will Be Lower

Opting for a single girder crane will save you money in a number of ways. As an example, it’s likely that your freight costs are going to be much lower. These kinds of savings can add up, and they could wind up paying off for you in a big way.

When you’re able to cut spending, your profits are likely to be higher. Lowering your freight costs — and some other expenses — could lead to significant savings. That money can be reinvested, allowing your business to grow.

It’s Ideal For Light And Medium Duty Cranes

While double girder gantry cranes are frequently recommended, it’s important to remember that these types of cranes aren’t going to be the best option in all circumstances. When it comes to light and medium duty cranes, a single girder crane is ultimately going to be the better buy.

Single girder cranes are the more economical option, and they are well-suited to these kinds of tasks. If you’re investing in a heavy-duty crane (grúa de servicio pesado), you might want to focus your attention on double girder cranes, but otherwise, single girder cranes are the right option.

Look into investing in a single girder overhead crane. Learn more about how these cranes are typically used and decide whether one of these cranes is the best fit for your needs. Double girder cranes can be very effective, but you could be better served by a single girder crane.

A Quick Overview Of Intermittent Asphalt Plant Parts

If you have invested money into an asphalt plant, you will know that upkeep will be necessary. Over the course of several years, it will likely not require any type of maintenance. However, there are certain parts that will need to be replaced over time. If you had yours for more than a decade, it is likely that you are familiar with the many parts that need to be replaced continuously. Here is an overview of the intermittent asphalt plant parts that you will likely need, as well as where you can get the best ones for affordable prices.

How To Ensure You Don’t Need Replacement Parts For Your Asphalt Plant

It should first be stated, if you are looking for an asphalt plant to purchase, that there are certain things you need to consider before purchasing one. Each of these is going to be designed to produce a substantial amount of asphalt daily. You must look at the type of mixer that they are using with the apparatus. Consider the mixing cycle that they use with the asphalt plant. Also consider the dust filters, the fuel that is used, and what the dry capacity actually is. Finally, consider the vibrating layer, the dust bag, and the asphalt tank(tanque de asfalto) that will come with the entire system. In the midst of all of this are certain parts that are likely to fail that you may need to replace at some point in the future.

Different Types Of Parts That You May Need For Your Asphalt Plant

There are certain parts that you may need to obtain overtime for your asphalt plant. These are just standard parts that you will become very familiar with. They are referred to as intermittent parts because, due to how the asphalt plant works, these are the most likely wants to break down over time. This may include wear plates, thrust rollers, silo parts, baghouse parts, and also valves that are used with the system. Additionally, the bearings, wheels, and the gear reducers(reductores de engranajes) are all components that you will have to maintain over time.

How To Find These For Lower Prices

Finding the lowest prices on these parts may require you to go outside of your immediate area. You must find a company that is larger, capable of producing them for a lower cost, just like AIMIX GROUP, and pass the savings on to the consumer. In the case of owners of asphalt mixing plant, they are always on the lookout for new businesses that can produce these components and a very low cost. Whether you need a variable frequency drive, trunnions, or air cylinders, the business that you choose should offer them at lower prices.

Maintaining an asphalt plant doesn’t have to be difficult. Although this is going to occur, you need to have access to parts that are affordably priced. If you are new to the industry, you should become familiar with the many different intermittent(discontinua) parts that you may need to replace on a regular basis. Whether this is burner safety switches, sprockets, or thermocouples that can burn out very easily, you need to have access to them at the lowest price possible. This will help your company save money, and also ensure that your entire system is able to produce asphalt at the highest possible rates.

Find And Pay A Fair Concrete Mixer Pump Price

Before you spend any money on a concrete mixer pump, you need to know where to get one for a good deal. That, and you need to know that the one you purchase is going to be in good working order. Here, you’re going to learn how to more easily find what you need.

Get to know what you’ll have to pay for what you’re getting. Don’t get something at random and then pay a concrete mixer pump machine price that you don’t know much about. It’s easy to figure out what this should cost you if you just shop around a little and figure out who is charging what. Once you know what a few companies have their mixer pumps set at price-wise, then you’ll be able to find out what a good price is. It’s always wise to shop around a little because then you’ll be able to get a deal that is more than worth it.

Save money

If you want to save a bit of money, you can buy a concrete mixer pump that has been lightly used. You don’t, however, want to buy something that is on its last legs because it could end up falling apart on you after just a few uses. Before you buy anything used, see if you can test out the pump to see what kind of shape it’s in before you spend anything. There are plenty of great options that are lightly used so don’t get something that’s of low quality if you want to be happy with your purchase.

A good price of concrete mixer with pump isn’t the only thing to look for. You also want to know if what you’re buying has a reputation for working nicely. Don’t randomly buy something without researching it a bit first so you know how it works and what it’s good for. You can generally find out more about a machine like this by looking up reviews about the exact make and model you’re checking out. Look to reviews that tell you what was good about a concrete mixer pump and what wasn’t good about it according to what past buyers have been saying.

Get warranty

Concrete mixer pumps may come with a warranty which is a good thing. You never know, for instance, if what you’re buying is going to break down on you after a few uses because it wasn’t built properly or has other issues that were bound to come up due to the way the pump was put together. If a mixer pump doesn’t have a warranty, then see if you’re able to send it back for a refund if you’re not happy with it after working with it once or twice. Make sure you test out what you get right away so you know if you want to return it or not before time is up and they won’t accept any returns.

Now you have a better idea of what it takes to find the best concrete mixer machine with pump price. This is something you need to buy with the right information in mind. That way, you don’t spend more than what is fair and you don’t get a bad mixer pump.

How To Choose The Best Bitumen Plant

When you need a bitumen batching plant you need to take your time because this helps you select the plant that meets your requirements and produces what you need. This plant produces high quality bitumen whenever you use it and the plant works reliably so you never have problems with it. If you are looking for this plant make sure that you follow these tips so you end up with the plant that is the best deal for your business.

The first thing you have to consider when you are looking for a bitumen plant is the price. You want to look for a price that you can afford and that is also in your price range. The plant comes in multiple price ranges so you need to think about the price range that is going to be the best fit for your needs.

Once you have a price figure out you can start working with the manufacturer. They will help you find the plant that is the best fit for your requirements and they will also work hard to keep you satisfied. You are going to need to know the features you need with this machine. Once you know the specifications that are needed for your project you can go ahead and start narrowing down the machines so you end up with the right one.

The bitumen plant is very efficient and it has a unique design that is very efficient so you can produce all of the bitumen that you need. This plant doesn’t use a lot of energy which makes it a great deal when you are trying to save money. Read more here.

The plant has a unique design that allows you to produce all of the bitumen that you need to complete your projects. The bitumen batching plant has a powerful drying drum that is also double insulated which means that it won’t feel hot to the outside. The operators can easily work the machine without having to feel hot.

Even the blades in the machine are made out of durable and high-quality steel which means they will last for a long time without needing any maintenance. The drum is very strong and it conducts heat well which means that you don’t have to spend a lot of money to heat it.

The design is easy to use and the temperature is very easy to control. The control unit is very easy to operate. The ignition system is easy to operate as well. The ignition system will ignite automatically which ensures that the system is safe and reliable.

The other part of the plant is the mixing system. The mixing system mixes the asphalt evenly and ensures that the asphalt is perfect each time you use it. There is a paddle that mixes the bitumen evenly and the paddles are made with the stongest metal which means that they won’t deform and will work with ease for a long time. This mini asphalt mixing plant is one of the best investments you can make.

Overview Of Small Portable Concrete Pump Philippines Companies

In the Philippines, the production of industrial equipment related to construction projects is always quite busy. You may be wondering how you would be able to find a small portable concrete pump that would originate from one of these businesses. Some of these companies have been producing them for decades and would provide you with a great discount if you were to approach them. This is particularly true if you are buying a large number of these small portable concrete pumps that you can use with your business. To get the best deals from small portable concrete pump Philippines businesses, let’s look at what your options are.

Philippine Companies That Produce Concrete Pumps That Are Portable

If you are going to produce substantially more business in the next six months, and you have a construction business that works with concrete, it might be time to make a small investment. Small portable concrete pumps can provide the necessary are production levels that are needed with minor jobs that you need to complete. The fact that they are portable means they are lightweight, easy to use, and there are many companies in the Philippines that make them. Look at the advertisements that are available, specifically looking for small portable concrete pumps.

Why Would You Need To Use Them?

It would be advantageous to use them for a couple of different reasons. First of all, for smaller jobs, they work just perfectly. They are also useful on larger jobs, particularly when you are trying to complete one and you have run out of all of your concrete. By mixing a small batch quickly, you can complete any project, ensuring that it will be done on time. If you have a small business, the smaller concrete pumps will be adequate. It’s also good to have them as a backup.

How To Save Money When You Purchase Them

If you want to save money, compare the different businesses in the Philippines that are producing these in mass quantity. Due to their size, and their limited capacity, you should be able to save a substantial amount of money. It is so important to look at other businesses, compare what they have, and get started as soon as you can. Most of these businesses are going to give you discounts on what is available, some of which will be the smaller concrete pumps. If you do your research and focus on getting only the smaller pumps, you should be able to find one fast.

Portable concrete pumps can be obtained in the Philippines rapidly. The smaller that they are, the less expensive they will be. Businesses that are producing them are likely going to be in competition with other companies that make them as well. By the end of the day, you should have contacted a couple of different companies, some of which will be willing to work with you. Eventually, you will make a purchase, obtaining one or more of them from a small portable concrete pump Philippines company that will deliver exactly what you want.

What You Need To Know About Concrete Mixer With Pump

Technological advancements in the construction industry have led to the introduction of some highly useful and effective construction equipment, key among them being the concrete pump with mixer. A concrete pump with mixer is a more recent type of concrete pump that integrates the functions of a traditional concrete mixer. This essentially means that you can effectively mix and pump high-quality concrete using the same machine. Besides the convenience of having two machines in one, there are many other reasons why this machine has become so popular amongst project managers.

Types of Concrete Pump with Mixer

There are two main types of concrete based on the type of engine; diesel and electric concrete pump with mixer.

i) Diesel Concrete Pump with Mixer

This version relies on a combustion engine for power. It is highly preferred since it can be used in any location and construction site – it doesn’t require the availability of electricity. It generally has more power than the electric version.

ii) Electric Concrete Pump with Mixer

The electric type is ideal for constructions in cities and urban areas, where there is a sufficient electricity supply. It has a high level of performance and requires less maintenance than the diesel version. Additionally, it has lower emission levels.

Benefits of Concrete Pump with Mixer

i) Quick Transportation

The concrete mixer with pump has a compact, lightweight design and comes with portability features. This makes it much easier to move it from one location to another than the larger fully-fledged concrete mixers and concrete pumps. Additionally, setting up a concrete mixer with pump for sale is quick and easy due to its compact design. There is no need for heavy lifting equipment or constructing a concrete foundation.

Thanks to its lightweight, your trucks won’t have to struggle as much when transporting them, which means reduced fuel costs.

ii) Small Foot Print

Another benefit of investing in a concrete mixer with pump is that you don’t have to worry about the lack of enough space. This machine can easily fit in most places where it may be difficult to set up a traditional concrete mixer or pompa beton mini. Thanks to this, it has a wide range of applications, including residential constructions, rural and urban housing, tunnels, bridges, and so on.

iii) Economical

Rather than buying two separate machines at full-price, it may make more economic sense to invest in a mobile concrete mixer with pump. This is especially so if you are just starting up your business or are running on a tight budget.

iv) Ease of Use

A concrete pump with mixer is incredibly easy to learn and operate. Additionally, most of the modern construction machines are highly automated, which minimizes the need for manual operations. One or two workers are enough to operate the machine.

v) High Mixing Speed and Pumping Capacity

The concrete mixer pump has the capability to produce high-quality concrete within a short period of time. In addition, it has a high pumping capacity is enough to meet the requirements of both small and medium scale projects. Learn more here.

The Best Reasons To Use A China Concrete Mixer Pump

Are you in the market for a mixer pump? Mixer pumps offer plenty of advantages, and you’ll be able to enjoy even more benefits if you choose a China concrete mixer pump. Read on to learn about why you should buy a concrete mixer pump (купить миксер с бетононасосом) from China.

They’re Fast And Easy To Work With

On job sites, it’s important to be able to set up equipment and get to work quickly. With the right mixer pump, you’ll be able to do that time and time again. These pumps are known for being easy to work with, and once they’re set up, they usually work very quickly.

Switching to using a mixer pump can save you quite a bit of time, and that can be very valuable. When you’re working with the right equipment, you’ll be able to get more done in less time, which can pay off for you in a big way.

You’ll Find Incredible Prices In China

Many people are drawn to buying equipment like this in China because it’s so easy to find excellent deals. When you do buy in China, you’ll be able to buy the equipment you want at a lower price tag overall.

While prices can vary based on the vendor you choose to work with, it’s likely that you’ll see big savings when you buy from China. If you compare the prices for pumps (миксер с бетононасосом цена) sold by vendors in China to the prices in other regions, you’ll see that this is the region you should be buying from.

There Are Plenty Of Excellent Options

Not only will you be able to find an effective pump at a fantastic price, but you won’t be limited in your options. There are many great options on the market, which will allow you to choose the pump that best fits your needs.

You’ll have the opportunity to look at a number of products and quite a few vendors when making your decision. You’ll be able to find the vendors that offer the best deals as well as the products that are most appealing to you. Having more choices usually benefits the consumer.

Concrete Pumps Can Save You Money

Not only are you likely to get a better deal on the pump that you buy, but in the long run, using a concrete pump could wind up saving you quite a bit of money. Most of the pumps on the market today are energy efficient, which means they aren’t expensive to operate.

As mentioned above, these pumps can also save you time, which can lead to significant financial savings. Because these pumps are so efficient, it’s also far less likely that you’ll run into problems when you’re on the job.

If you’re looking for equipment for your concrete mixing needs, you should strongly consider a China concrete mixer pump. As you can see, these kinds of pumps can offer you many benefits. Start looking at your options now so that you can decide if a pump like this would work for you. If you want to buy China concrete mixer pump, the company AIMIX in china is a good choice.

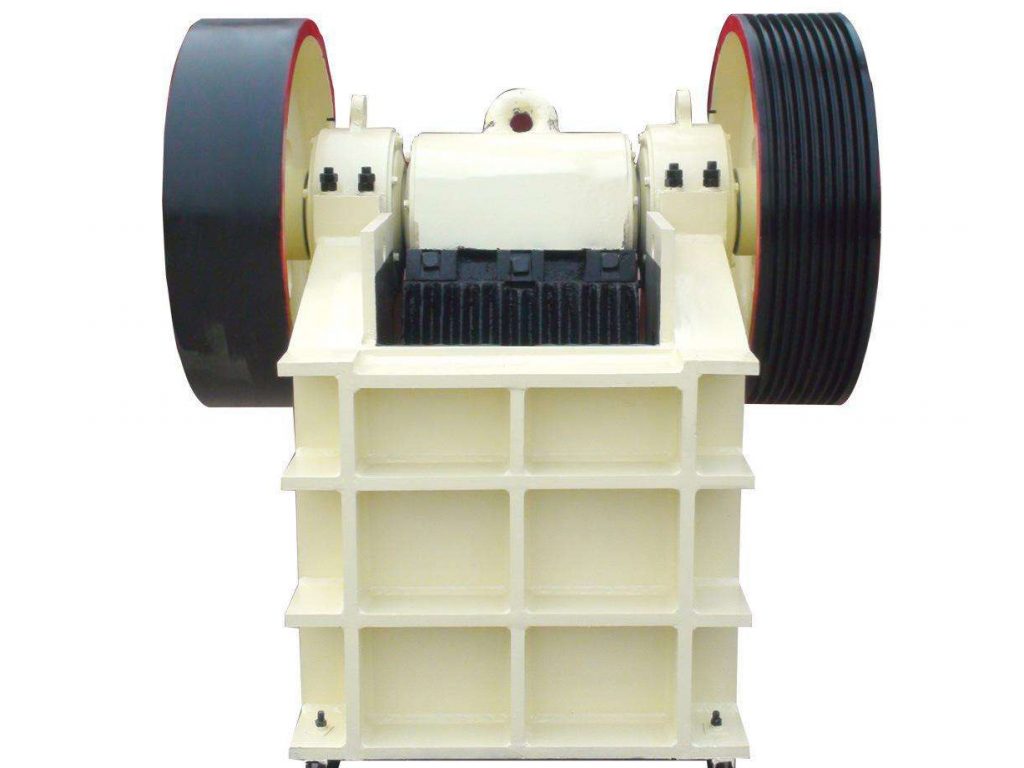

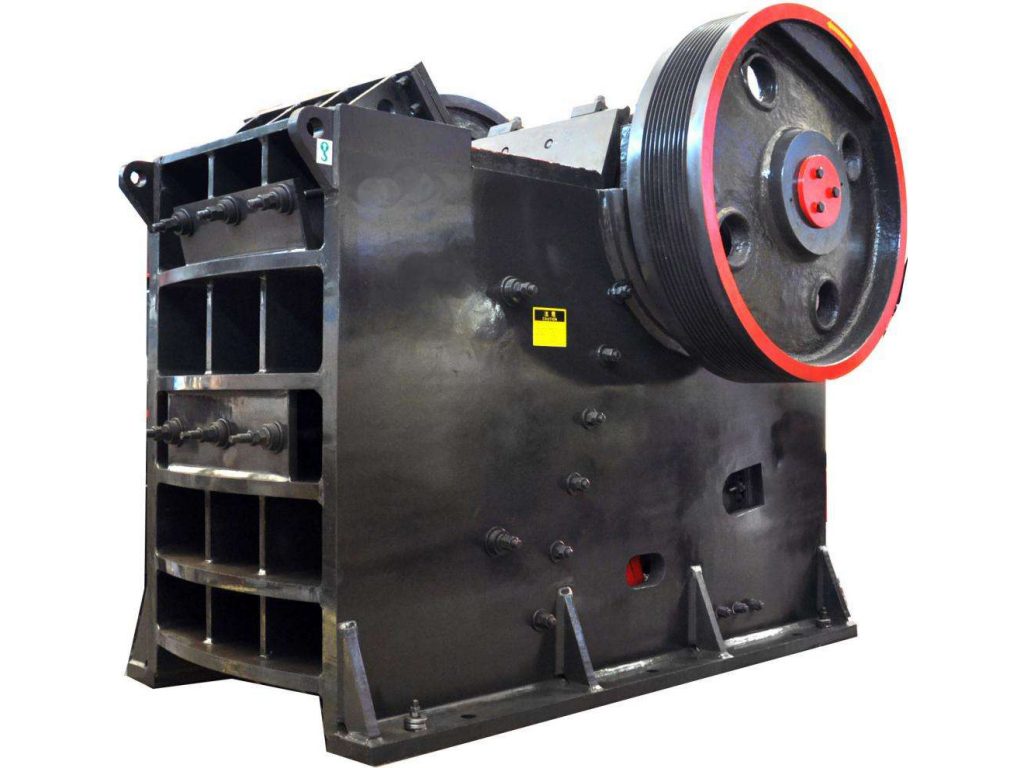

Everything You Should Know About Buying A Jaw Crusher

Are you planning to buy a jaw crusher? A jaw crusher is widely used in mines and other businesses where a powerful machine is needed to make quick work of huge stones in order to crush them into more manageable chunks. A jaw crusher is typically used as a primary crusher that breaks down big pieces of stones into manageable pieces which are then fed into secondary crushers to bring them down to the size as per the requirements.

In principle, all jaw crushers are the same as every machine has a stationary jaw and a moving jaw. The moving jaw pushes the stones against the stationary jaw at high pressure and this pressure ultimately breaks down the rocks into smaller pieces. However, there are many different types of jaw crushers and here is what you need to know in order to choose the right one for your business.

First and foremost, you should know that jaw crushers are widely used for coarse crushing as well as fine crushing(trituración gruesa y trituración fina). One of the most important parameters you need to look at is the type of materials that are going to be crushed in the machine. Different types of crushers are designed to be used for crushing of different types of materials which means you can’t really use a single piece of machinery in various mines.

Various properties of the minerals such as humidity, structure, hardness and production environment(entorno de producción), among other things, are typically used to choose the right jaw crusher. Another important thing that matters is the crushing capacity and production rate. If you are processing a huge amount of stones, you will need to invest in a machine with much higher capacity. Needless to say, higher capacity comes at a higher price. Do not make the mistake of choosing too much capacity as it typically lowers the operational efficiency and increases your overall production costs. Therefore, choose a capacity that is just ideal for your current as well as near-term future requirements.

When it comes to operational expenses, you need to look at the efficiency, power consumption, and crushing yield among other things. One of the most overlooked things in this business is the availability of spare parts. Some businesses make the mistake of buying a crusher that is available at a low initial cost but the manufacturers usually make money by supplying the replacement parts at a much higher price than average. Since these are proprietary components, buyers are forced to keep buying those components from the manufacturer itself. Therefore, you to pay special attention to the affordable availability of spare parts to keep your operational costs to the minimum.

When you start researching suppliers, you will find that there are many companies involved in this business but not every company has excellent reputation when it comes to quality of the machines as well as after sale service. You want to deal with a company that is known for quality of its products as well as after sales service. Therefore, choose a manufacturer like AIMIX Crusher(AIMIX Trituradora) only after carefully researching their reputation among their clients.

To conclude, a jaw crusher is widely used in the mining industry to break down big stones into smaller pieces. However, not all the crushers are the same. There are different types of crushers and the above-mentioned tips should help you in choosing the right one as per your business requirements.